application of carbon fiber in construction

The construction industry is rapidly developing due to the introduction of new technologies and materials. They increase the resistance of buildings to various loads and external influences. They extend their service life. Carbon fiber is often used to strengthen concrete, brick and other structures. The material has a number of properties, is easy to install and does not require maintenance. It significantly increases the strength and other characteristics of objects. What is carbon fiber, where and how it is used, we will tell you in our article.

Carbon Fiber: What is this material?

The product is a multilayer polymer substance with a composite structure. It is formed from the finest threads, up to 15 microns in size. They consist of carbon atoms that form a crystal-like network. The crystals are located parallel to each other, which provides the building material with excellent tensile strength.

What are they made of?

The raw material from which carbon is made is organic fibre. During production, everything except carbon atoms is removed from the original product. To do this, the material is oxidised with oxygen at a temperature of +250°C.

Pro Tip: Professional Foundation Repair in Guelph ON to ensure your property’s safety and stability. Call now for reliable solutions and a free inspection!

The second stage of production is heating to +800°C, and then to +1500°C in a nitrogen or argon environment. The carbonization process ends with the formation of a graphite structure in the material. The third stage is graphitization. The raw material is heated to +3000°C. Upon completion of the processing, no more than 1% of impurities remain in it. Carbon is made in the form of sheets, tapes, lamellas or yarn.

Basic requirements for production:

- Carbon fibers must be arranged parallel;

- To preserve the structure of the reinforcement components, a special fiberglass mesh is used;

- Carbon fiber is manufactured taking into account all technology standards to comply with current construction standards.

Main characteristics

Hydrocarbon fiber has a number of properties that are useful in construction:

- Excellent tensile strength.

- High adhesion to substrates with different structures – carbon fiber sheets are firmly fixed and do not peel off under mechanical or other influences.

- Oxidation resistance.

- Lightness and strength – with minimal weight, the materials can withstand heavy loads. Carbon is stronger than metal.

- Inertness to moisture and chemical compounds – the surface of the canvas is glossy, which prevents reactions with water and many substances.

- Impact resistance and fire resistance – carbon fiber does not support fire or contribute to its spread.

- Any type of repair is possible without completely closing the building and adjusting the operating mode.

- Ease of repair – can be carried out without the use of heavy construction equipment, complex equipment or the involvement of specialized specialists.

- Versatility – the materials are suitable for strengthening any structures. They are effective on uneven surfaces, rounded and angular parts, beam components, frame structures, etc.

To preserve its properties, before use, carbon fiber is impregnated with a 2-component epoxy resin, which acts as a binding component. After polymerization, the building material forms a reinforcing "corset" of exceptional strength. Carbon characteristics are preserved for 75 years.

Application

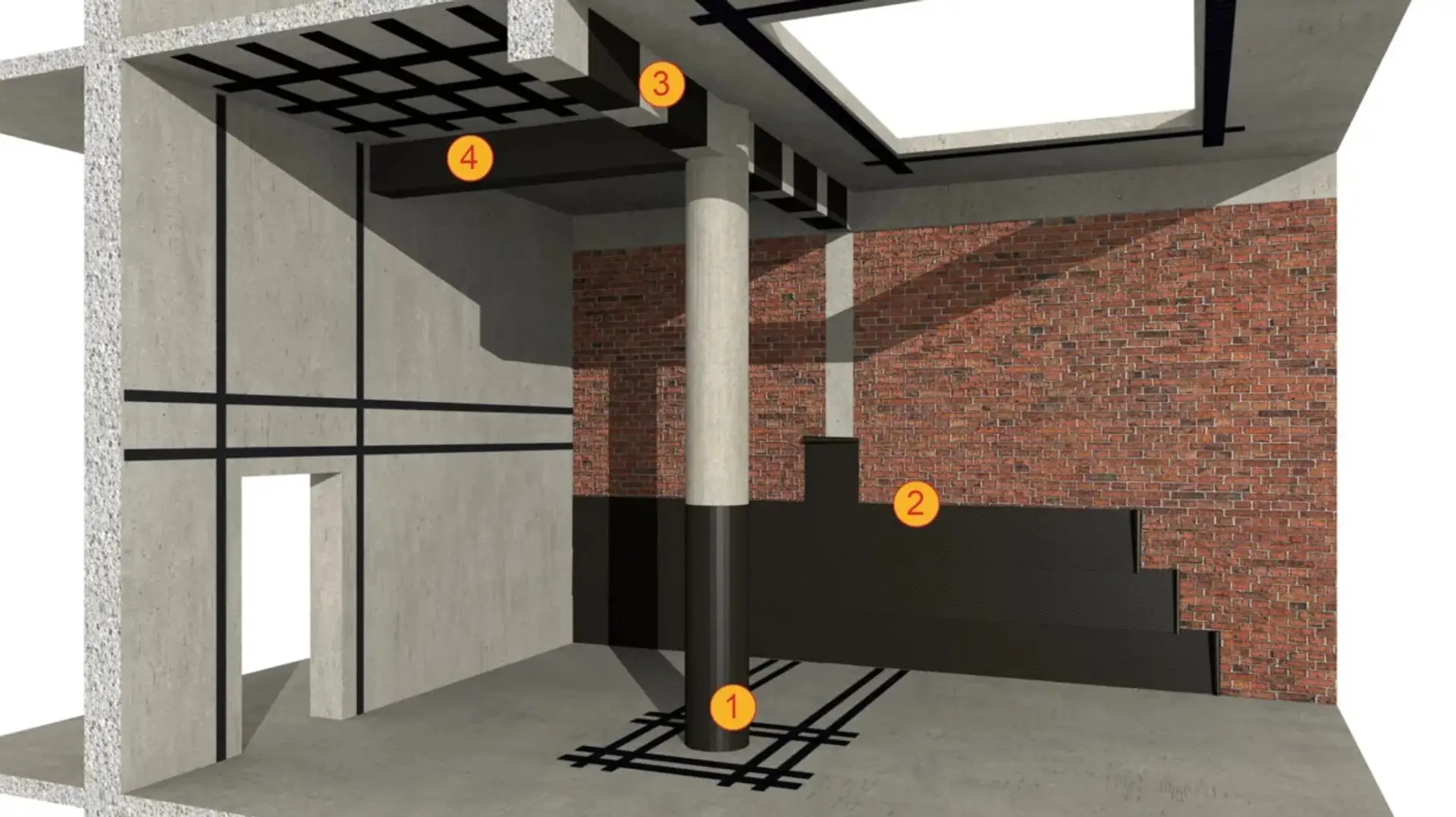

The efficiency and versatility of the material allows it to be used for reinforcing structures made of:

- Metal – these include steel frames, beams, ceilings, crossbars, etc. Steel structures are characterized by strength and elasticity indicators close to those of carbon fiber.

- Reinforced concrete – bridges, hydraulic structures, residential, industrial and commercial buildings, architectural monuments that require maintaining integrity and protection from impacts, weather influences, etc.

- Stone - pillars, walls of houses and pylons.

Carbon fiber is also suitable for reinforcing brickwork and wood structures in objects of any complexity and purpose. It is in demand during redevelopment, during which changes are made to load-bearing elements. It is used in the reconstruction of objects or changing the number of storeys of buildings. It is used in Moscow and other regions where ground movements occur.

The need for repairs of the listed and other buildings arises in the following cases:

- Damage to the foundations, which resulted in a reduction in bearing properties, rigidity and other parameters;

- Change in the operating conditions of the facility – increase in the magnitude and nature of loads, re-equipment, refurbishment or change of production;

- Construction of structures to improve their seismic resistance and increase the intervals between scheduled repairs;

- Long-term exposure of a building to mechanical loads or aggressive environments, which has led to cracking of concrete or other source material.

If carbon fiber is chosen as the main reinforcing element, the repair must be carried out in accordance with SP 164.1325800.2014.

Methodology for strengthening structures with carbon fiber

The work begins with preparing the base. The surface must be cleaned of old plaster, dirt and other particles, then make a structural marking of the areas to which the canvases will be attached. Cleaning is done manually, using sandblasting machines or angle grinders. The surface must be processed well, since the level of preparation of the base affects the result. If there are cracks, chips and other defects, they must be eliminated so that the coating is smooth.

Pro Tip: Enhance your property with a durable Concrete Driveway in Guelph ON. Contact us for expert installation and quality craftsmanship. Get your free quote today!

Next, the calculation of the reinforcement of the structures is carried out. The surveys are carried out by specialized engineers using professional equipment. The results of the calculations are entered into the reconstruction project

The next stage is the preparation of carbon fiber. It is important that dust and dirt do not get on the surface of the materials. Otherwise, the carbon fiber will not be able to soak well with epoxy resin. Therefore, before cutting the mesh or canvas, the surface is covered with polyethylene. Then, pieces of canvas are cut out according to the markings. Scissors or a knife are used. Upon completion, the prepared pieces are treated with epoxy resin.

The installation method on the repaired surfaces depends on the type of material. For example, the tape can be fixed dry or wet. In both cases, an adhesive layer is applied to the base beforehand. With the dry method, the tape is attached and impregnated only after rolling with a roller. With the wet method, the material is initially treated with an adhesive and then rolled with a roller.

Carbon sheets can be glued in two or more layers, depending on the design and extent of damage. Once hardened, the carbon fiber becomes smooth, so no further finishing is required.

When attaching carbon fiber lamellas, the bonding element is applied not only to the surface, but also to the material. After fixing, the lamellas are subject to rolling with a roller. The carbon mesh is attached to a concrete, pre-moistened base. It is fixed immediately after applying the adhesive and lightly pressed into the epoxy base. After application, you need to wait for the primary fixation. To increase the protective characteristics, an additional sealing layer is glued on top of the carbon fiber.

Upon completion of repairs, structures are strengthened, and the load-bearing properties of the main elements of the structures are restored. Tearing, pressing, or compressive loads on the foundation, load-bearing walls, and other foundations are removed or redistributed. In regions where earthquakes are possible, the seismic stability of buildings is increased.

Strengthening buildings and individual structures with carbon fiber is a progressive and cost-effective method of strengthening. Composites are much lighter and thinner than metal reinforcement and other similar components. Therefore, they do not put additional load on the foundations and do not reduce the useful space in the interior, which is important for buildings, both residential and industrial.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments