Automotive Composites Market Report, Size & Restraints, Forecast 2032

The global automotive composites market was valued at USD 7.67 billion in 2018 and is expected to expand to USD 13.5 billion by 2026, registering a CAGR of 7.56% during the forecast period. In 2018, North America held the leading share at 31.29%, while the U.S. market is projected to reach USD 3.22 billion by 2026, supported by the growing focus on lightweight vehicles and enhanced fuel efficiency.

The global automotive composites industry is experiencing a material revolution. As governments tighten emission standards and consumers demand more efficient vehicles, manufacturers are turning to innovative materials to strike the balance between performance, sustainability, and affordability. Among these, automotive composites are emerging as a game-changer. Lightweight, durable, and versatile, composites are reshaping how vehicles are designed and produced.

List of Top Automotive Composites Market Companies:

- Teijin Ltd.

- Mitsubishi Chemical Corporation

- Toray Industries, Inc.

- SGL Carbon

- RTP Company

- Plasan Carbon Composites

- Owens Corning

- Solvay S.A.

- UFP Technologies, Inc.

- BASF SE

- Other Players

Automotive Composites Market Importance in Automotive Design

One of the greatest challenges for automakers today is reducing vehicle weight without compromising safety, performance, or cost. Composites provide an effective solution. Glass fiber, carbon fiber, and natural fiber composites can significantly reduce vehicle mass when compared to traditional steel and even aluminum.

Glass fiber composites: Offer a weight reduction of around 15–20% and are widely used due to their cost-effectiveness and durability.

Carbon fiber composites: Deliver up to 40% weight savings, making them ideal for performance vehicles, though higher costs remain a challenge.

Natural fiber composites: Increasingly popular in interior applications, offering sustainability benefits and compliance with eco-friendly regulations.

For electric vehicles (EVs), lightweight materials are even more critical. Every kilogram saved translates into a longer driving range or the possibility of reducing battery size, improving cost efficiency. This has driven strong interest in composites for EV body panels, battery enclosures, and structural components.

Resin Trends Driving Market Growth

Automotive composites market are typically classified by the resin system used.

Thermoset resins currently dominate due to their high strength, dimensional stability, and excellent resistance to heat and stress. They are widely used in exterior body components and structural applications.

Thermoplastic resins are gaining momentum because of their recyclability, faster production cycles, and potential for mass production. However, challenges such as high melt viscosity and impregnation issues during processing still limit widespread adoption.

As automakers move toward circular economy practices, thermoplastic composites are expected to capture a larger share of future demand.

Key Applications of Automotive Composites Market

Automotive composites market are finding their way into multiple parts of the vehicle.

Exterior Applications – Body panels, hoods, headlamps, and bumpers dominate composite demand. These components not only reduce weight but also improve corrosion resistance and design flexibility.

Interior Applications – Natural fiber composites are increasingly replacing plastics in door panels, dashboards, and trim components, offering both weight reduction and eco-friendliness.

Structural and Powertrain Parts – Although still emerging, composites are being explored for use in chassis components, suspension systems, and under-the-hood applications where high strength and thermal resistance are critical.

Read More : https://www.fortunebusinessinsights.com/automotive-composites-market-102711

Growth Drivers

Several factors are fueling the rise of automotive composites market:

Light-weighting for Efficiency: Regulatory pressure for reduced CO₂ emissions has made weight reduction a top priority for automakers. Composites provide the most effective path to achieving this.

Electrification: EV adoption worldwide is accelerating composite demand due to the dual need for lightweighting and structural safety.

Sustainability Push: Growing consumer and regulatory demand for sustainable products is boosting the use of natural fiber composites and bio-based resins.

Design Flexibility: Composites allow for more innovative vehicle designs, enabling manufacturers to balance aesthetics with function.

Challenges and Restraints

Despite their benefits, composites face hurdles:

Recycling Issues: Separating fibers and resins at the end of life is complex and expensive. Current recycling processes are limited, making composites less attractive for circular economy initiatives.

High Costs: Carbon fiber composites remain expensive compared to metals. Thermoplastic composites, while recyclable, involve higher processing costs.

Scalability: Manufacturing composites at the scale and speed required by the automotive industry remains a challenge.

These barriers have slowed widespread adoption, particularly in mass-market vehicles.

Regional Insights

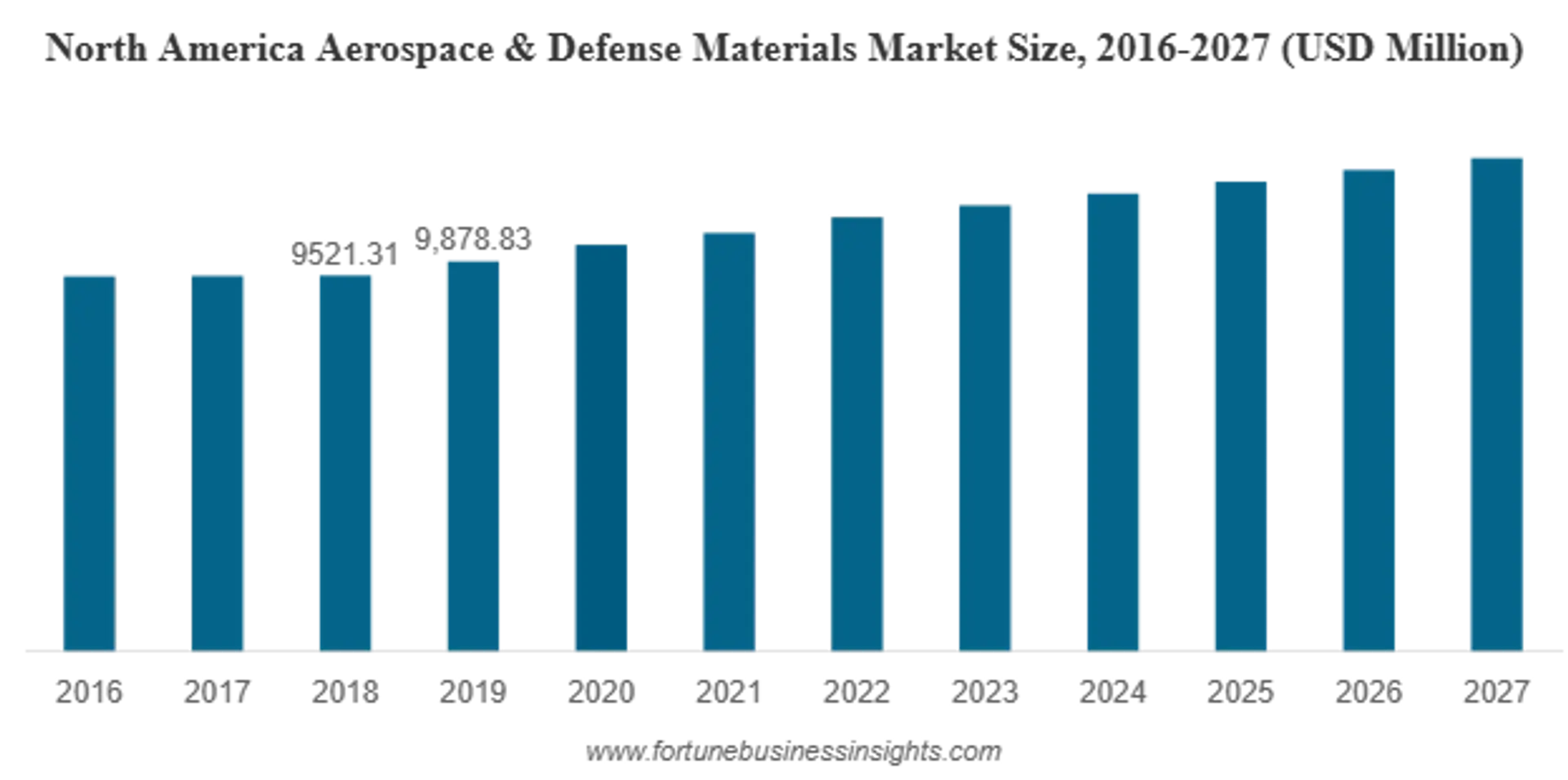

North America continues to dominate due to the presence of leading composite manufacturers, strong R&D capabilities, and adoption in performance and luxury vehicles.

Europe is driving sustainability efforts, leading to the growing use of natural fiber composites and stricter recycling mandates.

Asia Pacific is the fastest-growing region, with rising automotive production in China, India, and Thailand, and increasing consumer preference for lightweight vehicles.

Key Industry Developments:

February 2021 – Teijin Ltd. announced installation of glass fiber sheet molding compound line at the company’s automotive composites business named ‘Benet Automotive s.r.o’. The investment was done to meet growing demand for Teijin’s composite parts from European automotive manufacturers.

January 2021 – SGL Carbon announced investment of USD 4.5 million at its Arkansas site to expand the production of carbon composites for electric vehicles. The company is engaged in the manufacturing of carbon and glass fiber reinforced products for automotive applications. The new capacity addition will be used to meet growing demand for composite battery enclosures of modern e-car chassis.

Outlook for the Future

The future of the automotive composites market looks promising. With the shift toward electrification, stricter emission norms, and consumer demand for sustainable vehicles, composites are moving from niche applications to mainstream use. As recycling technologies improve and production costs decline, adoption is expected to accelerate further.

Automotive composites are no longer limited to luxury sports cars. They are becoming a necessity for mass-market vehicles aiming to meet the demands of the next generation of drivers. Companies that innovate in sustainable composite materials and scalable production technologies will shape the future of mobility.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments