Welded Wire Mesh Guide: Types, Benefits, and Uses

Welded wire mesh is a versatile material used across many industries, from construction to gardening. Its strength, durability, and affordability make it a go-to choice for countless applications. If you’ve ever wondered about various weld mesh panels available or how they can benefit your project, you’re in the right place. This guide will highlight what welded wire mesh panels are, the different types, common uses, advantages, and some tips for installation and care.

What Are Welded Wire Mesh Panels?

Welded wire mesh panels are sheets made from intersecting steel wires that are welded together at each intersection. The result is a strong, grid-like structure capable of supporting weight and resisting deformation. These panels are fabricated from steel wire mesh panels, which can be coated or treated for corrosion resistance.

What makes these panels stand out is their consistency and precision. Unlike woven wire fencing, welded wire mesh panels are uniform and exact in size, making installation straightforward. They’re used in everything from security fencing to concrete reinforcement, and even decorative paneling.

Types of Welded Wire Mesh Panels

When it comes to types of weld mesh panels, variety is key; different sizes, finishes, and grid configurations cater to different needs.

Standard Welded Wire Mesh Panels: The most common, available in various gauges and sizes, ideal for fencing and animal enclosures.

Heavy-Duty Steel Wire Mesh Panels: Thicker wires and tighter grids, perfect for industrial applications like fencing for high-security areas.

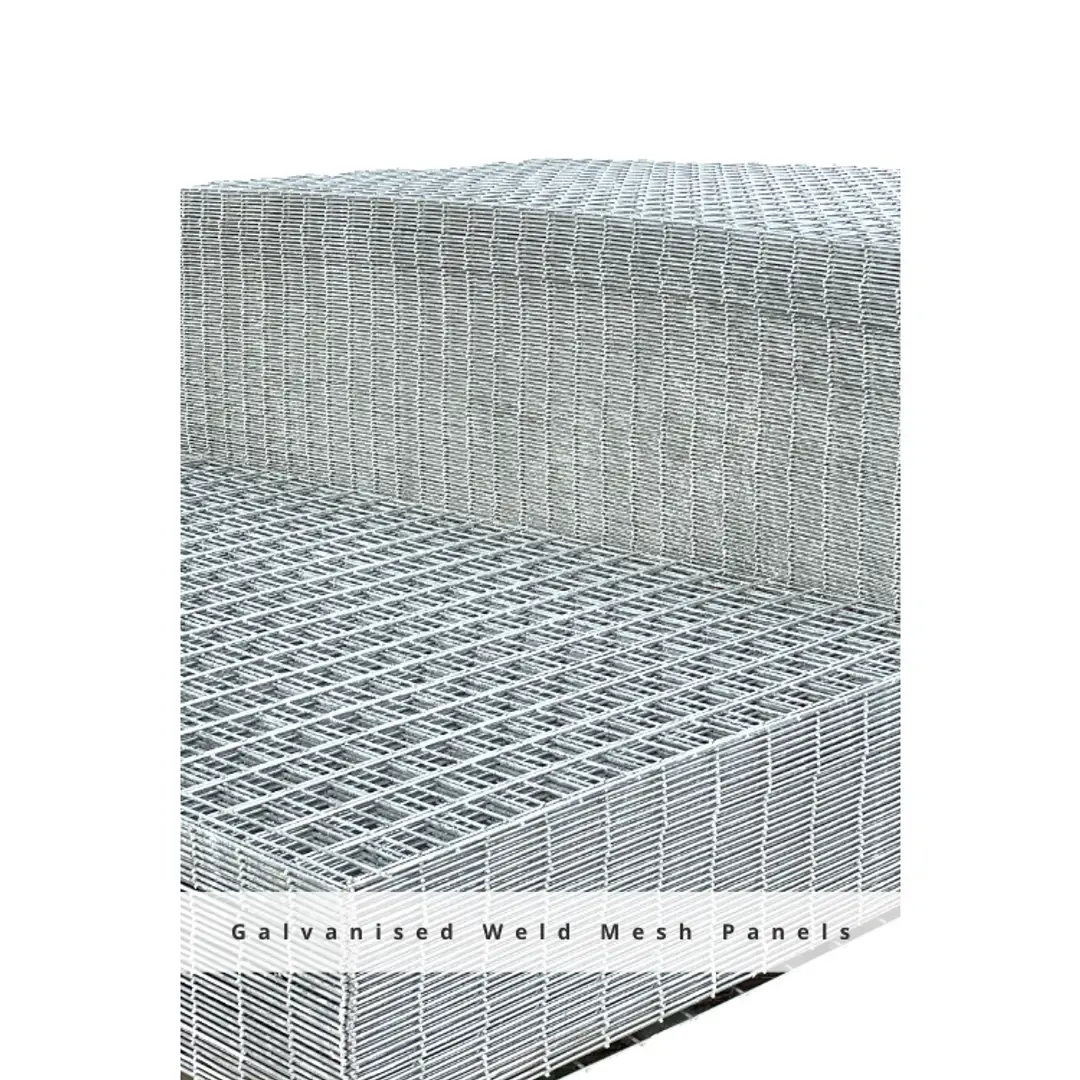

Galvanized Welded Wire Mesh: Coated with zinc, protects against rust and corrosion, suitable for outdoor use.

PVC-Coated Mesh: Adds a layer of plastic-coated finish for extra corrosion resistance and aesthetic appeal.

Welded Wire Mesh for Concrete Reinforcement: Thicker and more robust, designed to embed into concrete for added strength.

Each type offers unique benefits depending on your specific needs, whether that’s durability, appearance, or ease of installation.

Applications of Welded Wire Mesh Panels

Welded wire mesh panels find homes in numerous settings:

Fencing and Security: Steel wire mesh panels create secure boundaries around properties, farms, and construction sites.

Animal Enclosures: Used in zoos, farms, and pet cages, welded mesh panels keep animals safely contained while allowing good airflow.

Concrete Reinforcement: Welded wire mesh for concrete is standard in slabs, walls, and bridges, providing tensile strength.

Architectural Uses: Some designs incorporate wire mesh panels for decorative fencing or even interior partitions.

Gardening: Garden fencing and veils to protect plants from pests or to support climbing plants.

Industrial and Commercial: Heavy-duty panels are essential in warehouse compartments, machine guards, and storage solutions.

This wide range of applications emphasizes the flexibility of welded wire panels, whether for practical security or aesthetic purposes.

Benefits of Welded Wire Mesh Panels

Why do so many choose welded wire mesh panels over other fencing or reinforcement options? Here are some benefits:

- Consistency: Uniform panels mean predictable, straightforward installation, no surprises or modifications needed.

- Corrosion Resistance: Galvanised or coated options extend the lifespan in outdoor environments.

- Cost-Effective: Compared to solid metal panels, wire mesh panels come at a lower price point, offering excellent value.

- Easy to Install: Lightweight and strong, they can be quickly set up with basic tools.

- Versatility: Suitable for fencing, reinforcement, or decorative purposes.

It’s worth noting that some weaknesses exist, such as potential corrosion if not properly coated, or limited privacy due to the open grid design.

Installation Tips for Welded Wire Mesh Panels

Correct installation is vital to enjoying the benefits of weld mesh panels fully.

- Plan Your Layout: Mark out fence lines or areas where panels will be mounted.

- Use Appropriate Posts: Ensure posts are sturdy and properly spaced to support the panels.

- Secure Panels Properly: Use clips, ties, or clamps designed for wire mesh panels to ensure stability.

- Consider Ground Conditions: For outdoor fencing, embed posts deep into the ground and use concrete if necessary.

- Wear Protective Gear: Steel wire edges can be sharp; gloves and eye protection are recommended.

Taking time to plan can prevent common issues like misalignment or panels coming loose over time.

Maintenance and Care

While welded wire mesh panels are low-maintenance, some routine checks can protect your investment:

- Inspect for Damage: Look for bent wires, corrosion, or loose fittings; repair early to prevent escalation.

- Recoat if Necessary: For panels showing signs of rust, applying a rust-inhibiting paint or coating can prolong lifespan.

- Avoid Excessive Impact: Although tough, panels can sustain damage from heavy impacts; handle carefully during maintenance.

Proper care ensures your welded wire mesh panels remain functional and looking good for years.

Conclusion

Welded wire mesh panels are a practical, durable solution for countless applications, from fencing and animal enclosures to reinforcement in construction. Their various types, including galvanised steel wire mesh panels and heavy-duty options, make them adaptable to different environments.

Choosing the right panels depends on your specific use, whether you need something quick-to-install or a long-lasting, high-security barrier. The benefits, like strength, affordability, and ease of maintenance, make welded wire panels a reliable choice.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments