How Fuel Systems Test Service Prevents Failures and Reduces Costs

Fuel systems are evermore important these days keeping operations smooth in industrial, commercial, and home sectors. Fuel must be moving continuously and smoothly for the generation of power in generators, cars, or even heavy-duty equipment.

With leakage, contamination, or almost undetectable wear and tear on a system, all things can descend into unexpected downtime, repairing expenses, and dangers. Testing services work to tame the possible emergence of hassle in functioning performance. It also assists in long-term cost-effectiveness and even maintaining a relaxed mind by discovering the trouble to be cured well before it stands to worsen.

In this blog, we will discuss the role of fuel systems test service in preventing failures and reducing costs.

Overview of Fuel Systems Test Service

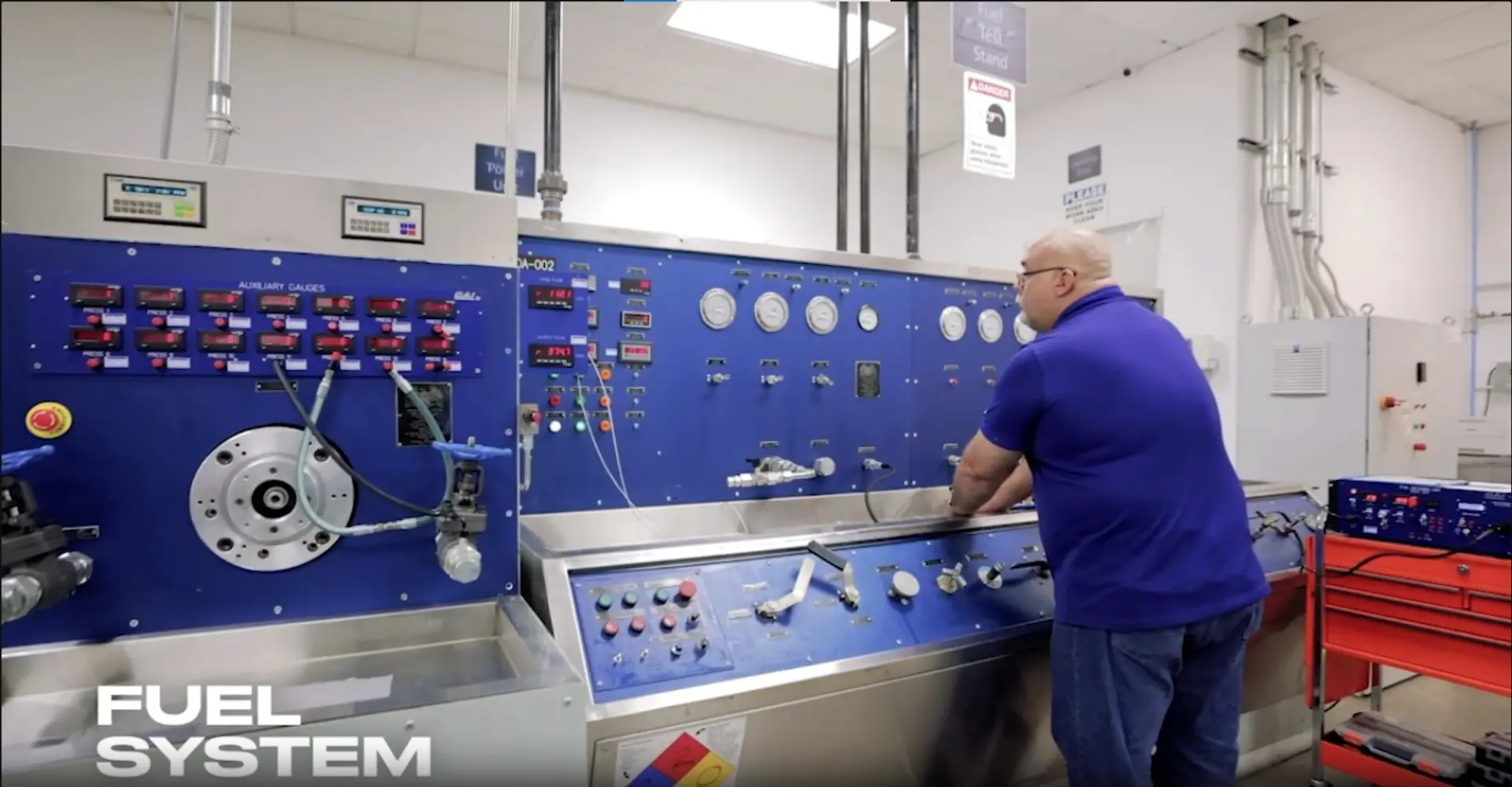

Fuel system testing consists of a focused process through which the systems of fuel are inspected for their condition, operation, and safety. It comprises inspections, diagnosis, and performance testing conducted to check leakage, contamination, obstruction, or lack of efficiency. The service is applicable to different types of systems like underground storage tanks, fuel pipes, generators, and pumping stations.

The testing could entail pressure testing, flow checks, contamination checks, and compliance inspections relevant to environmental and safety standards. These tests are performed to establish conditions for unexpected downtimes and compliance to standards. Modern monitoring of skilled resources is preventative, whereas maintenance becomes a corrective measure if the condition is reached. In periodic tests, advanced technologies are employed to get higher precision such as digital sensing, ultrasonic testing, and automated monitoring systems.

How Fuel Systems Test Service Avoids Failures

Fuel system failures do not occur overnight—rather, they build up slowly over time due to tiny, unknown problems. This is how testing avoids expensive interruptions:

Early Leak Detection

A continuous analysis detects any small leak in a pipe, tank, or valve before it becomes a major issue. Leaks cause loss of fuel, fire hazards, or soil contamination. Better leak detection benefits companies.

Contamination Control

Water, soil, and bacterial growth are all contaminants of fuel that clog filters and destroy equipment. Early detection of spoilage by testing services may save the contaminants and the fuel, facilitating correction through filtration or the cleaning of the tank.

Compliance with Safety Standards

Testing ensures that fuel systems adhere to regulatory safety and environmental standards. Compliance, aside from saving one from fines, reduces the possibilities of accidents and environmental harm.

Monitoring System Efficiency

Fuel system tests analyze flow rates and pressure levels to validate the system is operating at maximum efficiency. This minimizes the risk of performance failure that can bring operations to a standstill at critical moments.

Cost-Saving Advantages of Ongoing Testing

Regular testing is not merely preventing breakdowns, it is financially savvy too. Here’s how a fuel systems test service saves on costs in the long run:

Avoiding Emergency Repairs

Emergency repair services are usually costly when sudden breakdowns happen. Proper testing reduces such risks by addressing small problems before they mushroom into full-scale failures. Preventive measures always cost lower than emergency measures.

Increasing the Life of Equipment

Clean, efficient fuel distribution guarantees machinery and generators work efficiently for many years of operation. This lessens refurbishments and expensive replacements. Increased equipment life is one of the factors that boost the return on investments companies make.

Improving Fuel Efficiency

Systems properly tested remove wastes that are generated through leaks, inefficiencies, and contamination. Companies keep the bonuses of being able to save on fuel costs, while maximizing system output. Such improved efficiency reduces harmful environmental impact, adding to sustainability value.

Reducing Downtime

Sudden hangings or failures in plants stop production, hence loss in time and revenue. Preemptive testing, including checks such as hydraulic cracking pressure, guarantees productivity continuity to allow companies to meet production targets uninterrupted. Running continuously enhances customer confidence and trust in the supply chain.

In Summary

A well-working fuel system is the backbone of any industry, and its reliability should never be left to chance. Fuel systems test service investments save business owners and property owners from enormous expenses incurred during failures, and the same keeps them compliant while massive cost savings accrue. Regular testing keeps fuel systems efficient, safe, and reliable; uninterrupted operations ensue. The cost of downtime, repairs, or regulatory fines far exceeds test cost and therefore makes for wise and necessary investment by anyone who depends on the fuel-driven system. Next blog.......

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments