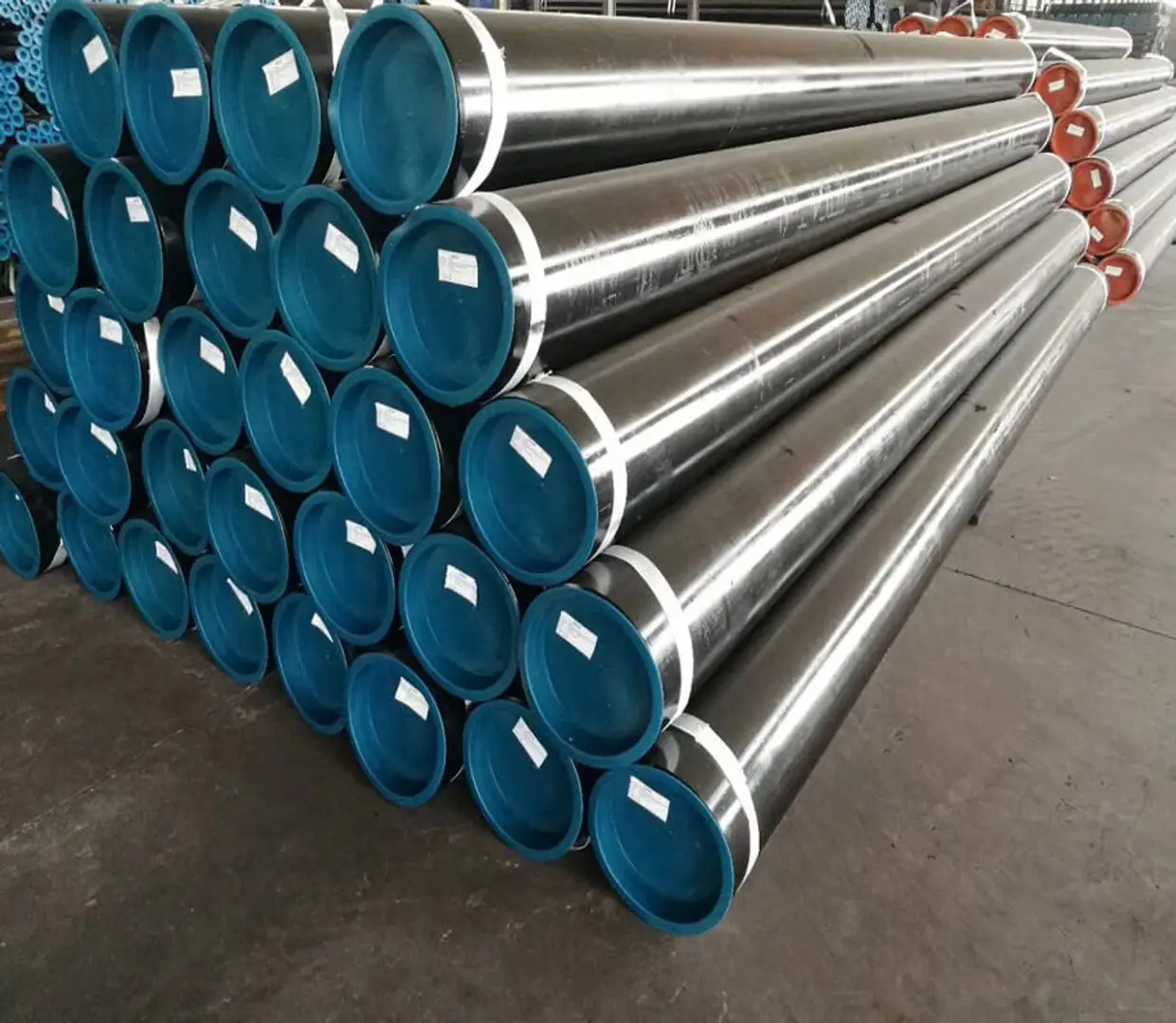

Alloy Steel ASTM A335 P1 Seamless Pipes – Properties, Applications, and Advantages

In today’s industrial environment, selecting the right piping material is crucial for ensuring performance, durability, and cost-effectiveness. One of the most trusted materials in the field of high-temperature and high-pressure piping systems is Alloy Steel ASTM A335 P1 Seamless Pipes. Engineered for strength, corrosion resistance, and excellent mechanical properties, these pipes are widely used in power plants, refineries, and petrochemical applications.

In this comprehensive blog, we will explore everything you need to know about ASTM A335 P1 seamless pipes, including their chemical composition, mechanical properties, benefits, applications, and why they are a preferred choice for critical operations.

What is ASTM A335 P1 Seamless Pipe?

ASTM A335 P1 refers to a specific grade of seamless ferritic alloy steel pipe that is primarily used for high-temperature service. These pipes are manufactured in accordance with the ASTM A335/A335M specification, which covers seamless ferritic alloy-steel pipe for high-temperature applications.

The “P” in P1 indicates the pipe’s pressure service, while “1” refers to the specific alloy content — in this case, Chromium-Molybdenum (Cr-Mo) based alloy steel.

Chemical Composition of ASTM A335 P1

The chemical composition of ASTM A335 P1 is carefully controlled to provide high-temperature strength and oxidation resistance. The typical composition is:

Element Content (%)

Carbon © 0.10–0.20

Manganese (Mn) 0.30–0.80

Phosphorus (P) ≤ 0.025

Sulfur (S) ≤ 0.025

Chromium (Cr) 0.50–0.80

Molybdenum (Mo) 0.44–0.65

The addition of Molybdenum increases the strength and high-temperature resistance, while Chromium enhances corrosion resistance.

Mechanical Properties of ASTM A335 P1

These pipes exhibit outstanding mechanical properties, making them suitable for demanding applications.

Property Value

Tensile Strength ≥ 380 MPa

Yield Strength ≥ 205 MPa

Elongation ≥ 30%

Hardness (HBW) ≤ 163

These values provide a strong indication of the pipe’s toughness and ductility, making them highly reliable under varying pressure and temperature conditions.

Key Features and Advantages

- High Temperature Resistance

- ASTM A335 P1 pipes are specifically engineered for elevated temperature service. They can withstand extreme thermal cycles without compromising structural integrity.

- Excellent Corrosion Resistance

- The presence of Chromium and Molybdenum improves the material’s resistance to oxidation and corrosion, even when exposed to steam and other aggressive media.

- Good Weldability and Fabrication

- These pipes can be easily welded and formed using standard fabrication techniques, making installation more efficient in large-scale projects.

- Long Service Life

- The high mechanical strength and resistance to scaling ensure that these pipes have a long operational lifespan, even in harsh industrial conditions.

- Consistent Quality

- Manufactured under strict quality standards, P1 seamless pipes deliver uniform wall thickness, excellent dimensional accuracy, and smooth internal surfaces — all of which contribute to optimal flow and reduced wear.

Applications of Alloy Steel ASTM A335 P1 Seamless Pipes

Due to their high-performance characteristics, A335 P1 seamless pipes are used in various industries where temperature and pressure play a critical role:

- Power Plants

- These pipes are extensively used in boiler tubes, heat exchangers, superheaters, and reheaters. They can endure high temperatures and fluctuating pressure levels common in thermal and nuclear power plants.

- Oil & Gas Industry

- P1 pipes are widely employed in the transportation of hot steam and hydrocarbons, especially in offshore drilling platforms, processing plants, and gas transmission pipelines.

- Petrochemical and Refineries

- They serve in refining operations involving high-pressure steam, process piping, and distillation towers where performance under thermal stress is crucial.

- Chemical Industries

- Used for conveying chemically aggressive fluids at elevated temperatures and pressures, these pipes are found in chemical reactors and synthesis units.

- Industrial Boilers

- Boiler manufacturers prefer P1 pipes for internal boiler tubing because of their excellent creep strength and resistance to high-temperature oxidation.

Manufacturing Process of A335 P1 Seamless Pipes

These pipes are manufactured using the hot extrusion or hot rolling process followed by heat treatment such as normalizing, tempering, or quenching. Here’s a brief overview of the steps:

Billet Selection – A high-quality alloy steel billet is selected and heated.

Hot Rolling / Extrusion – The billet is pierced and rolled to form a hollow tube.

Sizing & Stretching – The tube is stretched and sized to desired dimensions.

Heat Treatment – Pipes are treated to improve their mechanical properties.

Non-Destructive Testing – Includes ultrasonic, hydrostatic, and eddy current testing.

Inspection and Finishing – Visual and dimensional inspections are performed before marking and packaging.

Available Sizes and Specifications

Size Range: 1/2” NB to 36” NB

Thickness: SCH 20 to SCH XXS or custom

Length: Single Random, Double Random, or Cut Length

Ends: Plain, Beveled, or Threaded

Standards: ASTM A335, ASME SA335

Form: Round, Hydraulic, Straight

Why Choose ASTM A335 P1 Seamless Pipes?

Choosing ASTM A335 P1 seamless pipes provides several advantages, especially when long-term reliability and performance are top priorities. Industries around the world prefer these pipes for their ability to:

Maintain performance at high pressure and temperature

Resist thermal fatigue and creep rupture

Deliver cost-effectiveness over the lifecycle

Comply with global standards and specifications

Moreover, many reputed manufacturers offer customization in terms of size, schedule, and surface finish to meet project-specific requirements.

Certifications and Standards

Reputable suppliers ensure that A335 P1 seamless pipes comply with various international quality and safety standards, including:

ASTM / ASME standards

ISO 9001:2015

IBR (Indian Boiler Regulations)

PED (Pressure Equipment Directive)

Final Thoughts

Alloy Steel ASTM A335 P1 Seamless Pipes are the backbone of many high-temperature and high-pressure systems across power generation, oil & gas, and petrochemical industries. With their robust chemical makeup, excellent mechanical properties, and adaptability, these pipes are a smart choice for critical applications.

For industries seeking reliability, durability, and value, investing in ASTM A335 P1 pipes means ensuring performance today while planning for tomorrow. Whether for a boiler system or a heat exchanger network, these pipes offer unmatched dependability and service life.

Are You Looking for ASTM A335 P1 Pipes?

At Metinox Overseas, we specialize in providing high-quality ASTM A335 P1 seamless pipes in a range of sizes, grades, and finishes. Our products are sourced from trusted mills and come with full material traceability and test certificates.

Contact us today to get competitive pricing, custom sizes, or technical assistance for your next project.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments