CNC Milling Helps Manufacture Complex Parts with Precision

In today’s age of rapid industrial advancement, precision engineering plays a vital role in manufacturing. From aerospace to automotive and medical to consumer electronics, the demand for accurate, intricate, and high-quality parts continues to grow. One technology that stands out in meeting these expectations is CNC milling.

CNC milling has transformed traditional machining by combining mechanical precision with digital automation. It allows for the fabrication of highly complex parts with tight tolerances and excellent repeatability. This article explores what is CNC milling and how it works, and how it contributes to the efficient and precise creation of complex parts across multiple industries.

Understanding CNC Milling

To fully appreciate the benefits of CNC milling, it’s essential to understand what it is and how it functions within the broader context of modern manufacturing.

What is CNC Milling and How It Works

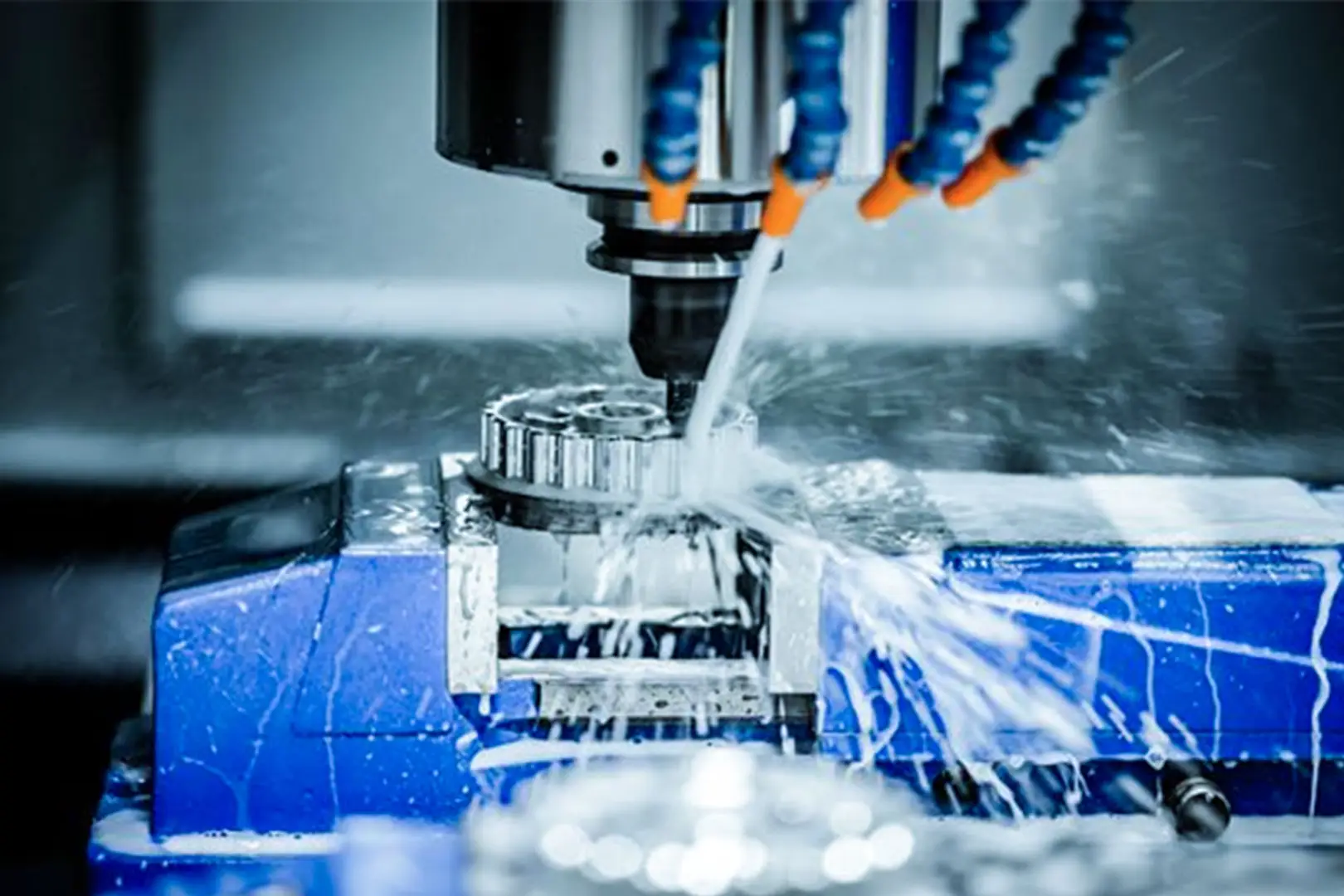

CNC stands for Computer Numerical Control, and milling is a type of subtractive manufacturing process that involves removing material from a workpiece using rotary cutters. CNC milling, therefore, refers to a computer-controlled machining process where a milling machine cuts and shapes material based on programmed instructions.

In simple terms, the process begins with a digital design, usually created in CAD (Computer-Aided Design) software. This design is then translated into a CNC program using CAM (Computer-Aided Manufacturing) software. The CNC program guides the milling machine’s movement, determining where and how the cutting tools engage the material.

The machine follows these instructions to carve out the final part from a solid block or plate of material, usually metal or plastic. CNC milling can produce components with incredibly detailed geometries, ensuring accuracy down to fractions of a millimeter.

Components of a CNC Milling System

Understanding the key components involved in a CNC milling setup can help explain how the process achieves its remarkable precision.

The Milling Machine

The core of CNC milling is the milling machine itself. These machines come in vertical or horizontal configurations and may feature multiple axes of movement—typically 3, 4, or even 5 axes. More axes allow for more complex machining operations.

Cutting Tools

Milling machines use rotary cutting tools, such as end mills and drills, to remove material. These tools are selected based on the geometry of the part and the material being cut.

Workholding Devices

Clamps, vises, or fixtures are used to securely hold the raw material (also known as the workpiece) in place during the machining process.

CNC Controller

The CNC controller is the brain of the operation. It reads the G-code (the machine language created by CAM software) and translates it into precise mechanical motions that control the machine’s axis, speed, tool changes, and coolant flow.

Types of CNC Milling Processes

CNC milling can be customized in several ways to meet different manufacturing needs. Different types of milling processes enable the production of a wide range of shapes and surface finishes.

Face Milling

Face milling involves cutting with the end of the cutting tool to produce a flat surface. It is commonly used to prepare the surface of a workpiece for further operations.

Peripheral Milling

In peripheral milling, the cutting takes place along the sides of the tool, allowing the machine to carve deeper grooves, slots, or shapes along the sides of the material.

Angular Milling

Angular milling is used to create surfaces that are not parallel or perpendicular to the machine’s main axis. This is often employed in creating angled grooves or chamfers.

Form Milling

Form milling uses a uniquely shaped cutting tool to produce irregular or curved profiles. It is ideal for manufacturing complex contours and patterns.

Materials Used in CNC Milling

CNC milling is extremely versatile and compatible with a wide variety of materials, making it ideal for diverse applications.

Metals

Metals such as aluminum, stainless steel, brass, titanium, and copper are commonly milled. These materials are used for parts that require strength, durability, or heat resistance.

Plastics

Engineering plastics like ABS, nylon, polycarbonate, and PEEK are also widely used. These materials are lighter and suitable for prototypes, housings, and insulating components.

Composites and Others

CNC milling can also be applied to composites, ceramics, and even wood, depending on the application requirements and tool compatibility.

Advantages of CNC Milling for Complex Parts

CNC milling provides several significant benefits that make it the preferred choice for manufacturing detailed and precise components.

High Precision and Accuracy

The computer-controlled nature of CNC milling ensures consistency and high accuracy in every run. It allows manufacturers to meet extremely tight tolerances, which is critical in industries like aerospace and medical device manufacturing.

Consistency and Repeatability

CNC milling machines can produce multiple identical parts without variation, making them ideal for both prototyping and full-scale production.

Complex Geometries

One of the most compelling advantages is the ability to produce intricate and complex part geometries that would be challenging or impossible using manual machining.

Reduced Human Error

By automating most of the process, CNC milling reduces the chances of operator error, leading to higher quality and fewer defects.

Scalability

Whether you need a single prototype or thousands of production units, CNC milling scales efficiently to meet various production volumes.

Industries That Rely on CNC Milling

CNC milling is a critical manufacturing method in many industries that demand precision and performance.

Aerospace Industry

The aerospace sector uses CNC milling for components such as turbine blades, engine mounts, and structural supports. Precision is non-negotiable, and CNC ensures reliability and quality.

Automotive Industry

In the automotive industry, CNC milling helps in the production of engine parts, suspension components, and mold tools. The process supports rapid prototyping as well as mass production.

Medical and Dental

CNC milling is widely used for surgical instruments, orthopedic implants, dental prosthetics, and custom medical devices. Each component must meet strict dimensional and material standards.

Consumer Electronics

From housings to connectors and mounting brackets, CNC milling helps develop parts with fine features for smartphones, laptops, and other electronics.

Industrial Machinery

CNC-milled parts form the backbone of industrial equipment, including gears, shafts, and tooling fixtures that require strength and high wear resistance.

Limitations and Challenges of CNC Milling

Despite its advantages, CNC milling comes with some limitations that manufacturers must consider.

High Initial Investment

CNC machines, especially multi-axis systems, are expensive to purchase and maintain. However, the return on investment is usually strong over time.

Skilled Programming Required

Even though the machines are automated, they require skilled operators to program the tool paths, select tools, and set up workpieces.

Material Waste

As a subtractive manufacturing process, CNC milling results in material waste, especially when machining from solid blocks. Efficient planning and recycling can mitigate this.

Future Trends in CNC Milling

The field of CNC milling is evolving rapidly with advancements in technology and digital manufacturing.

Integration with Automation and Robotics

Modern CNC milling machines are increasingly integrated with robotic arms for automated loading and unloading, reducing downtime and labor costs.

Smart Manufacturing and IoT

CNC machines are now being connected to networks, allowing for real-time monitoring, predictive maintenance, and enhanced production planning.

Hybrid Manufacturing

Combining CNC milling with additive manufacturing (3D printing) is becoming more popular, offering the best of both subtractive and additive technologies.

Sustainable Machining Practices

Eco-friendly coolants, energy-efficient machines, and recyclable materials are helping to make CNC milling a more sustainable process.

CNC Milling vs. Other Machining Processes

Understanding how CNC milling compares to other methods can help in choosing the right approach for a specific application.

CNC Milling vs. CNC Turning

While milling uses rotating tools and stationary workpieces, CNC turning involves rotating the workpiece against a stationary cutting tool. Milling is better suited for complex surfaces and angular features, while turning excels in cylindrical parts.

CNC Milling vs. 3D Printing

3D printing builds parts layer by layer, making it suitable for prototypes and custom shapes. CNC milling, being subtractive, is better for functional parts requiring high strength and surface finish.

CNC Milling vs. Manual Machining

Manual machining requires hands-on control of the cutting process. CNC milling removes this variability and dramatically increases productivity and repeatability.

Conclusion

CNC milling has become a cornerstone of modern manufacturing, offering unmatched precision and efficiency. By understanding what is CNC milling and how it works, it’s clear that the technology has revolutionized the way industries approach part production. Whether it’s creating a single prototype or running a high-volume production line, CNC milling delivers complex, accurate, and reliable parts with remarkable consistency.

As technology continues to advance, CNC milling will only become more capable and accessible—driving innovation and setting new standards for precision in manufacturing.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments