Industrial 3D Printing Speeds Up Prototype Development Process

In today’s competitive industrial landscape, speed and precision are crucial to the product development cycle. Businesses no longer have the luxury of long lead times or expensive tooling when creating prototypes. This is where industrial 3D printing for prototypes steps in, offering a revolutionary approach to rapid, accurate, and cost-effective prototyping.

With the advancement of additive manufacturing technologies, companies are now able to build physical models directly from digital files, accelerating the entire innovation process. This article explores how industrial 3D printing is changing the way prototypes are developed, its benefits, applications, and the future of prototyping.

Understanding Industrial 3D Printing

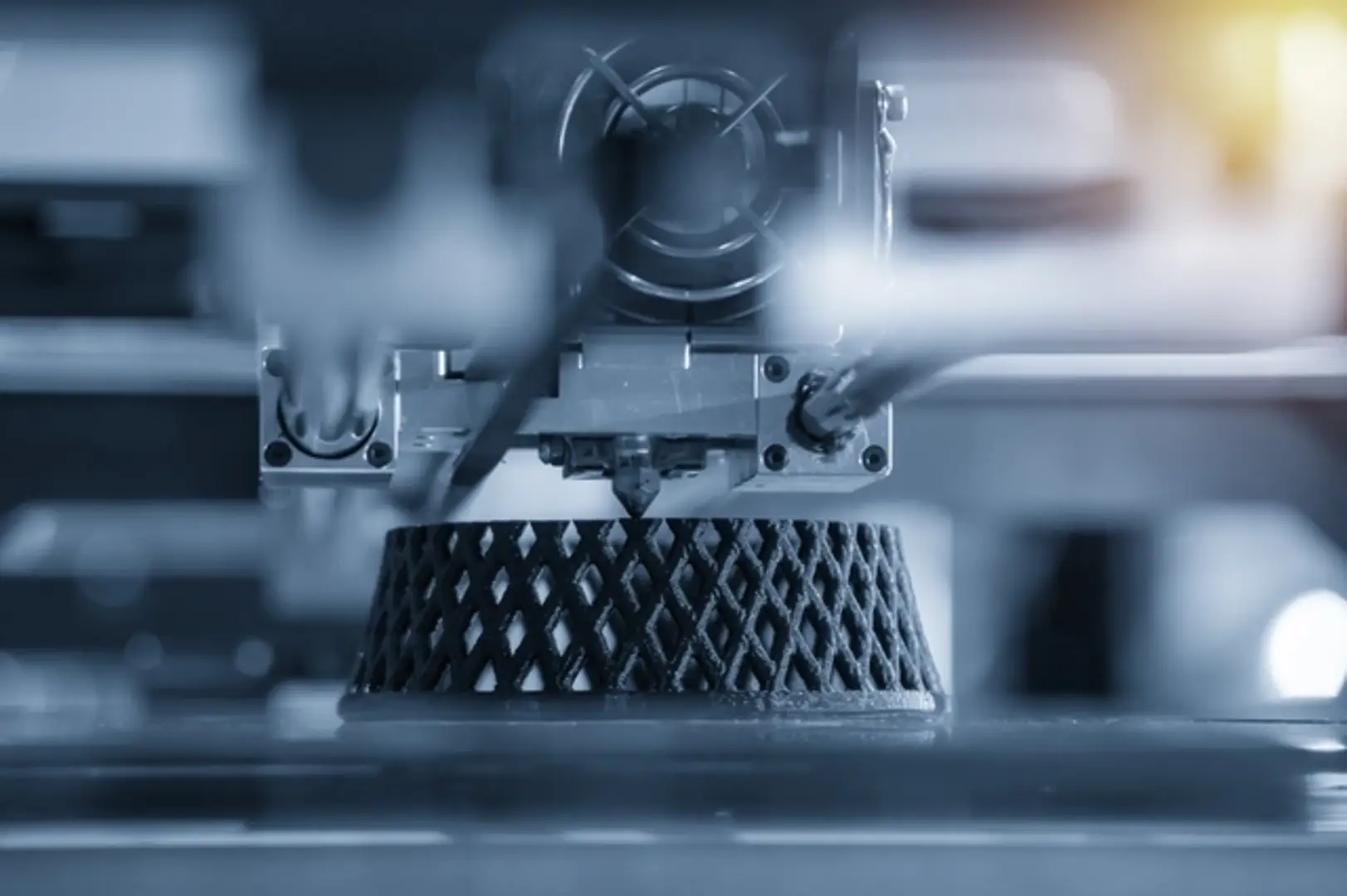

Industrial 3D printing, often referred to as additive manufacturing, involves creating three-dimensional objects by layering materials based on digital designs. Unlike traditional subtractive methods like milling or cutting, 3D printing builds an object layer-by-layer, which leads to minimal material waste and greater design flexibility.

How Industrial 3D Printing Works

The process begins with a CAD (Computer-Aided Design) file that serves as the blueprint. This file is fed into a 3D printer, which then slices the model into thin layers and prints each layer using a chosen material—ranging from plastics to metals, resins, and composites.

Depending on the technology used, such as FDM (Fused Deposition Modeling), SLA (Stereolithography), or SLS (Selective Laser Sintering), different materials and printing methods can be applied to meet the needs of the prototype.

The Role of Prototyping in Product Development

Prototyping is a critical phase in product design and development. It allows designers and engineers to test concepts, refine designs, and identify flaws early in the process before committing to full-scale production.

Traditional Prototyping Challenges

Conventional prototyping often requires time-consuming steps, such as tool manufacturing, molding, machining, and assembly. These processes are not only slow but also expensive—especially when multiple iterations are needed.

Some common challenges include:

Long lead times for producing tools or molds

High material and labor costs

Limited design flexibility

Difficulty in producing complex geometries

The Need for Speed and Flexibility

Modern markets demand faster product cycles, often with customization options and iterative testing. Industrial 3D printing for prototypes directly addresses these needs by reducing development times from weeks to days and allowing on-the-fly design changes without high costs.

Benefits of Industrial 3D Printing for Prototypes

The advantages of using industrial 3D printing for prototypes are numerous. These benefits are not just limited to time and cost savings but also include improved product quality and innovation.

Rapid Turnaround Time

One of the most significant benefits is speed. Prototypes that used to take weeks to fabricate can now be produced in a matter of hours or days. This enables faster decision-making, shorter project timelines, and quicker time-to-market.

Cost Savings

Because there is no need for specialized tooling or molds, the cost of producing prototypes is dramatically reduced. This is especially beneficial for low-volume runs or single-use prototype parts.

Enhanced Design Freedom

Industrial 3D printing enables the creation of complex geometries, including hollow structures, intricate internal features, and organic shapes that are impossible with traditional manufacturing methods.

Iterative Testing and Refinement

With 3D printing, companies can easily test multiple versions of a product design, make adjustments, and print new versions—without restarting the manufacturing process each time.

On-Demand Production

Prototypes can be created as needed, reducing inventory requirements and allowing engineers to respond quickly to feedback or new ideas.

Types of 3D Printing Technologies for Industrial Prototypes

Not all 3D printers are created equal. Industrial applications require high-performance technologies that can deliver precise and durable parts suitable for testing and presentation.

Fused Deposition Modeling (FDM)

FDM is the most widely used 3D printing method. It extrudes melted thermoplastic filament layer by layer. It’s ideal for functional prototypes that require durability but not necessarily fine detail.

Stereolithography (SLA)

SLA uses a UV laser to cure liquid resin into hardened plastic. It’s excellent for producing high-resolution prototypes with smooth surfaces and fine details.

Selective Laser Sintering (SLS)

SLS uses a laser to fuse powdered materials (typically nylon). It creates strong, functional prototypes without needing support structures and is suitable for testing mechanical properties.

Direct Metal Laser Sintering (DMLS)

DMLS is used for metal parts and is perfect for industries such as aerospace and automotive that require robust, end-use metal prototypes.

Real-World Applications of Industrial 3D Printing for Prototypes

Across industries, companies are taking advantage of industrial 3D printing for prototypes to accelerate product innovation and enhance R&D.

Automotive Industry

In automotive design, prototypes of car parts, brackets, and custom fittings are frequently created using industrial 3D printing. This allows manufacturers to test part fitment, airflow, and structural performance.

Aerospace Sector

Aerospace firms use 3D printing to develop lightweight, complex components like air ducts, brackets, and housings. Prototypes are tested for strength, aerodynamics, and heat resistance before production.

Medical and Healthcare

Medical device companies use 3D printing to create prototypes of surgical instruments, implants, and custom prosthetics. This is especially useful for personalized medicine, where every patient may require a unique solution.

Consumer Products

From electronics to home appliances, companies prototype enclosures, buttons, and interfaces with 3D printing. It helps validate design aesthetics, ergonomics, and user interaction before mass production.

Industrial Equipment

Manufacturers of industrial machinery often 3D print tooling, jigs, and fixture prototypes. This helps optimize manufacturing lines and improve product quality without costly downtime.

Workflow Integration with 3D Printing

Integrating industrial 3D printing into the prototype development workflow enhances efficiency and allows companies to scale their innovation processes.

CAD and Simulation

Designers begin with CAD software and often run simulations before printing to identify stress points or potential failure areas. Once validated digitally, the design moves to the 3D printer.

In-House vs. Outsourcing

Many companies invest in their own industrial 3D printers for maximum control and faster turnaround. Others outsource to service bureaus depending on the scale and material requirements of their project.

Post-Processing

After printing, parts may require post-processing steps such as cleaning, curing, sanding, or machining—depending on the material and final application.

Challenges and Considerations

While the benefits are compelling, it’s important to be aware of certain limitations and considerations with industrial 3D printing for prototypes.

Material Limitations

Not all materials are available or suitable for every type of 3D printer. Certain mechanical or thermal properties may require specific technologies that are more expensive.

Surface Finish and Accuracy

Some 3D printing methods may result in layer lines or rough surfaces that require finishing for aesthetic or functional purposes.

Initial Investment

High-end industrial 3D printers can be costly. However, these costs are often justified by the long-term savings in development time and production flexibility.

The Future of Industrial 3D Printing in Prototyping

The future of industrial 3D printing for prototypes is bright. As materials improve, print speeds increase, and software becomes more powerful, the line between prototyping and final production continues to blur.

Hybrid Manufacturing

Many companies are adopting hybrid workflows, combining additive and subtractive methods to get the best of both worlds—rapid prototyping and precision finishing.

Mass Customization

As demand grows for personalized products, 3D printing offers a path to cost-effective mass customization that traditional methods can’t match.

Sustainability

3D printing generates less waste, and researchers are developing recyclable and bio-based materials, making it a more sustainable option for future manufacturing.

Conclusion

Industrial 3D printing has fundamentally changed the way prototypes are developed. By offering speed, precision, flexibility, and cost-effectiveness, it empowers companies to innovate faster and more efficiently. From concept to creation, industrial 3D printing for prototypes accelerates the entire product development process—transforming ideas into reality with unmatched speed and agility.

As the technology continues to evolve, its role in prototyping will only grow more vital. Businesses that embrace industrial 3D printing early are not just improving their product development—they’re redefining what’s possible.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments