Roller Press Machine Boosts Industrial Material Compression Efficiency

In today’s competitive industrial landscape, manufacturers are continuously looking for ways to optimize efficiency, reduce energy consumption, and improve material handling. One piece of equipment that plays a significant role in these improvements is the roller press machine. Known for its ability to compress, compact, and densify materials effectively, the roller press machine has become indispensable in sectors like cement production, metallurgy, chemical processing, and mineral processing.

This article explores the working principles of the roller press machine, its applications, benefits, and how it enhances material compression efficiency in various industrial processes.

Understanding the Roller Press Machine

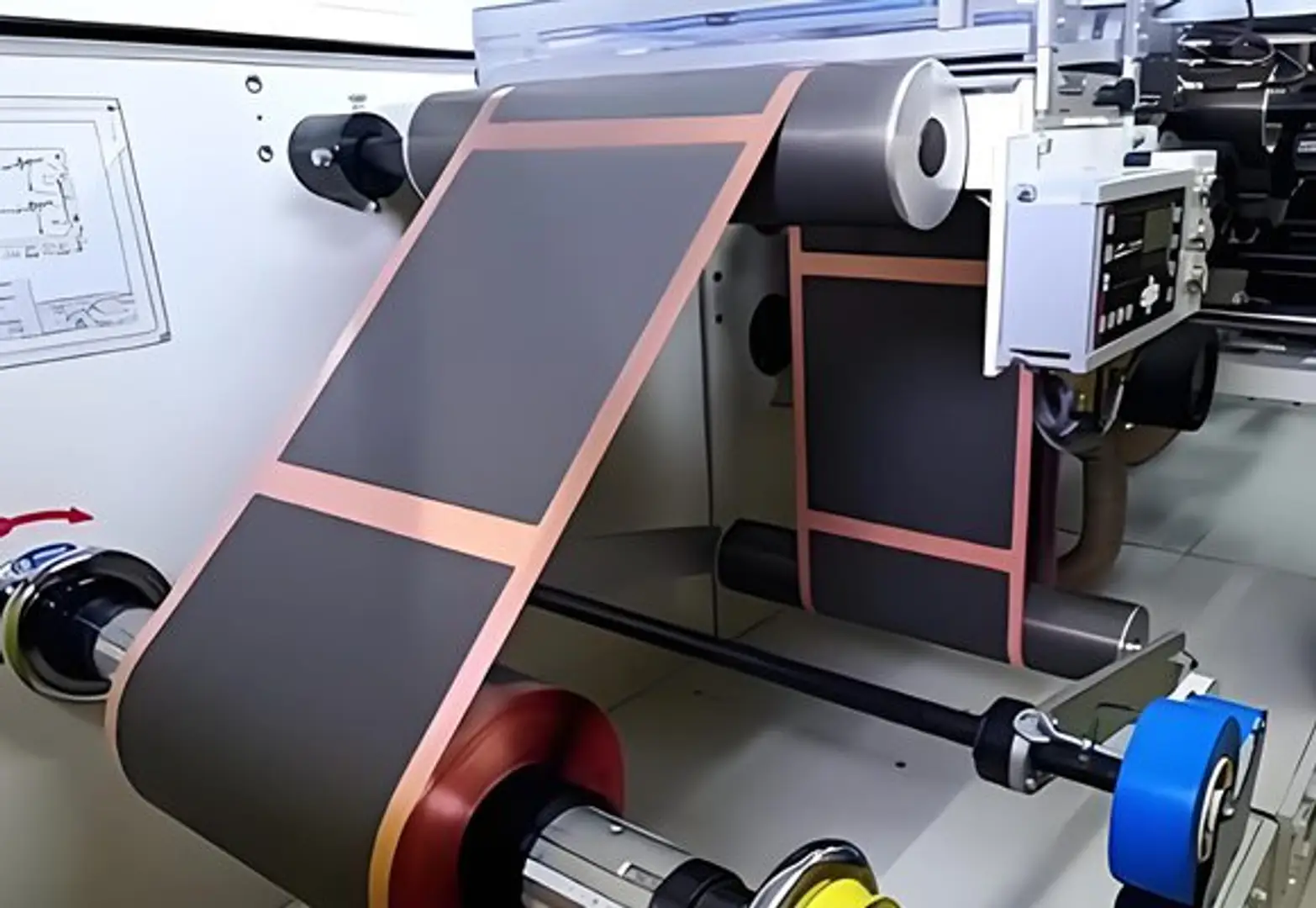

What Is a Roller Press Machine?

A roller press machine is a type of mechanical equipment designed to apply high pressure to bulk materials by passing them through two counter-rotating rollers. These rollers compress the material into a compacted, dense form, which is ideal for subsequent processing or handling. The machine is often used for dry powder compaction and granulation.

Basic Components of a Roller Press Machine

Rollers: Heavy-duty cylindrical components that rotate against each other.

Feeding System: Mechanism that delivers raw material into the rollers.

Hydraulic System: Controls the applied pressure on the materials.

Drive Unit: Powers the movement of the rollers.

Frame and Housing: Provides structural support and safety coverage.

Working Principle of the Roller Press Machine

Compression Through High Pressure

The roller press machine operates on the principle of high-pressure grinding or compaction. Material is fed between two rollers rotating in opposite directions. As the material enters the gap, it is subjected to extreme pressure. This compacts the particles and forms a dense layer or briquette, depending on the application.

Material Flow and Compaction Zone

Pre-Compression Zone: The material is introduced and partially compressed.

Compression Zone: Maximum pressure is applied, and particles are densified.

Release Zone: Compressed material exits the rollers in a solid or granulated form.

Key Applications of the Roller Press Machine

- Cement and Construction Materials

- The roller press machine is widely used in cement plants for grinding raw material and clinker. It improves grinding efficiency while reducing energy use.

- Metallurgy and Mining

- In the metallurgical industry, roller presses compact metal ores or other fine materials before smelting, enhancing the process’s overall efficiency.

- Chemical and Fertilizer Industries

- Chemical compounds and fertilizers are often in powdered form. A roller press machine compacts these powders into uniform granules, improving flowability and packaging.

- Ceramic and Glass Manufacturing

- The roller press machine helps compact ceramic powders for sintering and molding processes, contributing to improved product quality.

- Waste and Recycling

- Roller presses are also used in recycling systems to compress waste materials like sludge, reducing volume and preparing it for further treatment.

How Roller Press Machines Enhance Compression Efficiency

Consistent Pressure Distribution

The uniform pressure applied by the rollers ensures consistent compaction across the material bed. This uniformity leads to better control over density and structure.

Energy-Efficient Operation

Compared to traditional grinding mills, the roller press machine consumes significantly less energy. The high-pressure mechanism is designed to reduce friction and mechanical losses.

High Throughput with Compact Design

Roller press machines can handle large volumes of material without requiring large footprints. This makes them ideal for facilities aiming to maximize space usage while increasing productivity.

Reduced Dust and Material Loss

Since the material is compressed into a solid form, there is less airborne dust and loss during transportation and handling. This also contributes to a cleaner working environment.

Benefits of Using a Roller Press Machine

Improved Product Quality

By delivering uniform density and structure, roller presses ensure higher quality of the final product. This is especially important in industries like ceramics and pharmaceuticals.

Lower Operating Costs

The reduction in energy consumption and minimized material waste result in lower operational costs over time. Maintenance requirements are also minimal due to the robust design.

Increased Production Speed

The roller press machine can operate continuously with minimal interruptions, significantly increasing output rates compared to batch-based systems.

Eco-Friendly Processing

Reduced energy use and minimized material loss contribute to sustainable industrial practices. Many modern roller press systems also recycle materials within the system.

Design and Customization Options

Roller Surface Design

Roller surfaces can be smooth or patterned, depending on the material and required compaction level. Corrugated or grooved surfaces improve grip and pressure distribution.

Adjustable Pressure Settings

Modern roller press machines offer adjustable pressure controls to suit different materials and desired compression levels. This enhances flexibility in manufacturing.

Cooling and Heating Systems

Some materials require specific temperature conditions during compaction. Roller presses can be equipped with heating or cooling systems to maintain ideal processing temperatures.

Factors Affecting Roller Press Machine Performance

Material Characteristics

Particle size, moisture content, and flowability affect how the material responds to compression. Proper material pre-treatment can enhance roller press efficiency.

Roller Speed and Pressure

Higher speeds and pressures can increase throughput but may reduce compaction uniformity. Optimizing these parameters is key to maintaining quality and efficiency.

Maintenance and Roller Wear

Roller surfaces wear out over time, especially with abrasive materials. Regular inspection and resurfacing maintain machine performance and output consistency.

Safety and Operational Considerations

Operator Training

Operators should be trained in handling the machine safely and adjusting settings according to material types. This minimizes risk and ensures optimal results.

Emergency Stop and Overload Protection

Modern roller press machines include safety features like emergency stops, overload sensors, and interlock systems to prevent accidents.

Dust Control Systems

Integrated dust collectors or enclosed feeding systems reduce environmental hazards and improve workplace air quality.

Integration into Industrial Systems

Compatibility with Conveyors and Feeders

Roller press machines can be integrated with upstream and downstream equipment like conveyors, feeders, and granulators to streamline production.

Automation and Monitoring

Advanced systems allow remote monitoring of parameters such as roller speed, temperature, and pressure. This enables predictive maintenance and operational optimization.

Innovations in Roller Press Machine Technology

Digital Control Systems

With the rise of Industry 4.0, roller press machines are now equipped with digital control systems for real-time adjustment and data logging.

Hybrid Roller Press Designs

Innovative designs combine the benefits of traditional roller presses with auxiliary systems like pre-crushers or screening units, enhancing overall process efficiency.

Eco-Conscious Materials and Design

Newer models are constructed with recyclable materials and energy-efficient motors, reflecting the growing demand for sustainable manufacturing solutions.

Comparing Roller Press Machines to Alternative Technologies

vs. Ball Mills

While ball mills grind material by impact and friction, roller presses compress it directly. The roller press machine is generally more energy-efficient and produces less heat.

vs. Briquetting Machines

Both machines compact material, but roller presses typically work with finer powders and are more suitable for high-throughput applications.

Common Challenges and Solutions

Material Buildup on Rollers

Sticky or moist materials may cause buildup. Regular cleaning and using non-stick coatings can alleviate this issue.

Uneven Compaction

This may result from uneven feed distribution or worn-out rollers. Adjusting feed systems and timely roller maintenance can solve the problem.

Future Outlook of Roller Press Machines

Increasing Demand in Sustainable Manufacturing

As industries aim to reduce carbon footprints, energy-efficient equipment like the roller press machine will see increased adoption.

Expansion into New Industries

Emerging sectors such as battery recycling and bio-material processing are beginning to utilize roller press technology for material densification.

Smart Monitoring and AI Integration

Future roller press systems may incorporate AI to predict maintenance needs, optimize performance, and adjust settings automatically based on material input.

Conclusion

The roller press machine is a powerful tool for improving industrial material compression efficiency. With its ability to reduce energy usage, increase output, and improve product quality, it stands as a cornerstone in modern manufacturing processes. From cement and mining to chemicals and recycling, this versatile machine delivers consistent performance and long-term benefits.

As technology advances, the roller press machine will continue to evolve—adopting smart systems, eco-friendly designs, and greater integration into automated production lines. For any industry looking to enhance compression efficiency and achieve sustainable production goals, investing in a high-quality roller press machine is a smart and future-forward decision.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments