5 Common Mistakes When Installing Radiant Floor Heating Systems in Concrete Slabs

Installing radiant floor heating systems in concrete slabs is a smart way to keep your home warm from the ground up. But mistakes during installation can lead to uneven heating, system failure, and expensive repairs. Whether you’re building new or renovating, avoiding these common errors can save time and money.

1. Skipping Insulation Beneath the Slab

One of the biggest mistakes people make is skipping the insulation layer under the concrete. Without insulation, much of the heat escapes downward into the soil instead of rising into the room.

Why it’s a Problem:

- Reduces energy efficiency

- Slows down the heating response time

- Increases operating costs

Fix:

Always install a high-quality rigid insulation board beneath the slab. This keeps heat where you want it — in your living space.

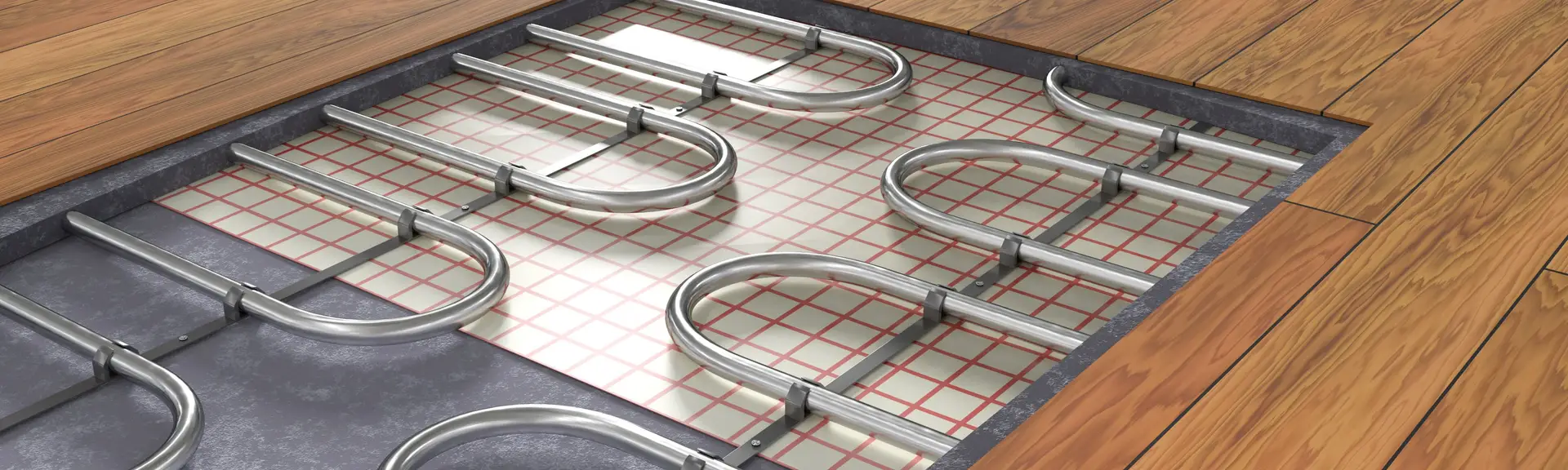

2. Poor Tubing Layout or Spacing

A poor tubing layout leads to cold spots, overheating zones, and inefficient energy use. This happens when the installer doesn’t follow a uniform loop spacing or places tubing too close or too far apart.

What to watch for:

● Inconsistent tubing distances

● Sharp bends or kinks

● Overlapping loops

To get the most from radiant floor heating systems concrete slab, spacing needs to be calculated based on room size, heat load, and type of flooring.

3. Incorrect Water Temperature Settings

Hydronic radiant floor heat uses warm water circulated through tubing to heat the space. If the water temperature is too high, it can damage the flooring or cause overheating. If too low, it won’t heat the room effectively.

Tip:

● Use a mixing valve or temperature control system

● Check the flooring manufacturer’s recommendations

Hydronic radiant floor heat systems work best when temperatures are optimized for comfort and safety.

4. Forgetting to Pressure Test the System

It might seem obvious, but some skip the step of pressure-testing the tubing before pouring the slab. This is a critical check to catch leaks or weaknesses in the tubing.

Why it matters:

● Fixing a leak after the concrete is poured is costly

● Testing ensures long-term system reliability

Always pressure test the tubing and joints with water or air before the concrete pour. Don’t assume it’s fine just because it looks okay.

5. Not Using a Professional for Design & Layout

Many homeowners try DIY or hire general contractors unfamiliar with radiant systems. The design of radiant floor heating systems, concrete slab installations, requires specific calculations for load, layout, and zoning.

Problems this causes:

● Inadequate heating

● Overuse of materials

● System failure over time

The fix:

Get your layout professionally designed, especially if you’re going for a multi-zone system or working in a climate with extreme cold.

Bonus: Failing to Plan for Flooring Compatibility

Not all flooring materials work well with heated slabs. Hardwood, for instance, needs to be engineered or designed for radiant compatibility.

Tips:

● Use tile, polished concrete, or radiant-safe engineered wood

● Avoid thick carpets or traditional hardwoods

When designing with radiant floor heating systems concrete slab, always consider the final flooring material in your heat load calculations.

Final Thoughts

Installing radiant heat under concrete isn’t overly complex, but it does require attention to detail. With proper planning, correct materials, and professional guidance, you can enjoy warm, efficient heating that lasts decades.

Avoiding the mistakes above will ensure that your radiant floor heating system’s concrete slab delivers the comfort and savings they’re known for.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments