VFD and PLC: The Power Duo Behind Efficient Industrial Automation

VFD and PLC technologies are the foundation of modern industrial automation systems. When used together, a Variable Frequency Drive (VFD) and a Programmable Logic Controller (PLC) create a powerful and flexible solution for controlling motors, machinery, and complex processes. These two technologies enable precise control, energy efficiency, and system intelligence across industries such as manufacturing, HVAC, water treatment, and more.

In this article, we’ll explore how VFD and PLC systems work together, the benefits of integrating them, common applications, and why partnering with a trusted automation expert like Xtreme Automation LLC can help you implement seamless, scalable control systems that maximize performance and minimize costs.

Understanding the Basics of VFD and PLC

What is a VFD?

A Variable Frequency Drive (VFD) is an electronic device that controls the speed and torque of an electric motor by varying the frequency and voltage of its power supply. VFDs are commonly used in applications that require motor speed adjustments, such as pumps, fans, conveyors, and mixers.

What is a PLC?

A Programmable Logic Controller (PLC) is an industrial-grade computer used to automate mechanical processes. It monitors inputs from sensors and other devices, processes logic instructions, and sends outputs to control actuators like motors, valves, and relays.

When VFD and PLC systems are integrated, the PLC acts as the brains of the operation, sending commands to the VFD based on system conditions and user-defined logic.

Benefits of Integrating VFD and PLC Systems

Combining VFD and PLC technologies brings multiple operational advantages:

1. Energy Efficiency

By allowing motors to run only as fast as necessary, VFDs reduce energy consumption significantly. When controlled by a PLC, speed adjustments can be made dynamically based on sensor inputs, setpoints, or system conditions.

2. Improved Process Control

PLCs provide advanced control logic, timers, counters, and feedback mechanisms. This allows for highly precise control of VFDs to meet complex operational needs such as batch processing, ramp-up/down speeds, and multi-motor coordination.

3. Extended Equipment Life

Gradual motor starts and stops using VFDs reduce mechanical stress, while PLCs can monitor fault conditions and initiate safe shutdowns, minimizing wear and tear on your equipment.

4. Real-Time Monitoring

Integrated systems allow for real-time feedback and system diagnostics via HMIs or SCADA systems, enabling better decision-making and predictive maintenance.

5. Reduced Downtime

Smart VFD and PLC setups can detect anomalies, send alerts, and activate backup routines automatically—helping to avoid costly unplanned shutdowns.

Industries That Rely on VFD and PLC Systems

A wide range of industries benefit from integrating VFD and PLC systems:

- Manufacturing & Packaging: Automating conveyors, mixers, and assembly lines

- Water & Wastewater Treatment: Managing pump speeds based on demand or tank levels

- HVAC Systems: Controlling fans, compressors, and cooling towers for optimal energy use

- Food & Beverage: Batch processing, filling, and sorting lines

- Agriculture: Irrigation control and grain handling systems

In each of these applications, precise control and automation are critical to maximizing productivity and minimizing operational costs.

Custom VFD and PLC Solutions from Xtreme Automation LLC

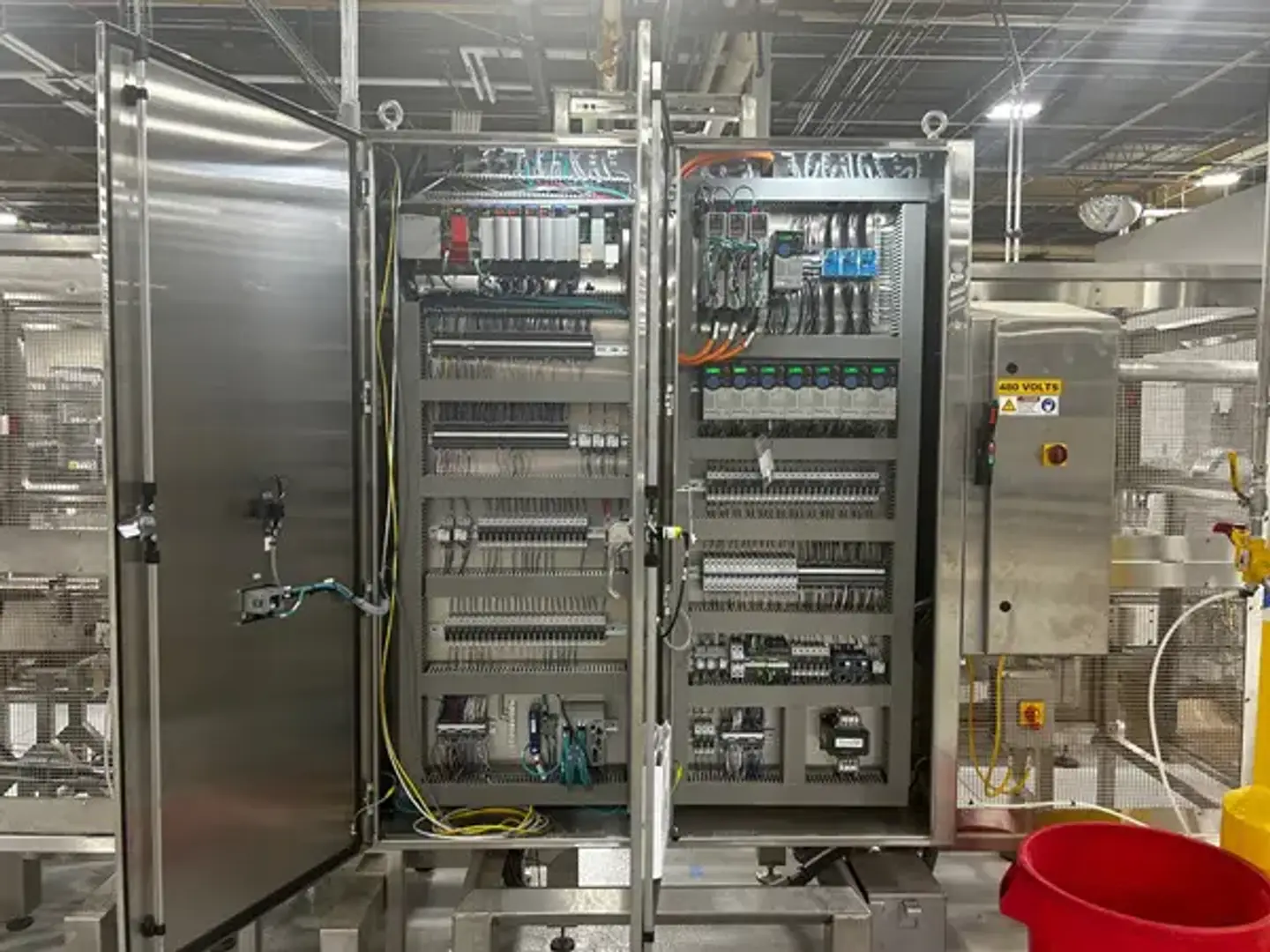

If you’re looking to optimize your industrial or commercial system with VFD and PLC integration, Xtreme Automation LLC offers full-service automation solutions tailored to your specific needs. With deep expertise in industrial controls, panel fabrication, and process optimization, they help clients achieve safer, smarter, and more efficient operations.

Xtreme Automation LLC provides:

- UL508A-certified control panel design and fabrication

- Custom PLC programming and logic development

- VFD integration, setup, and tuning

- HMI design and system visualization

- SCADA and remote monitoring solutions

- On-site installation, testing, and technical support

Their team works closely with each client to deliver turnkey solutions that enhance performance, reliability, and scalability.

How the Integration Process Works

The process of integrating VFD and PLC systems typically includes:

- Consultation & Needs Assessment – Understanding your application, load demands, and control requirements.

- System Design – Developing electrical schematics, control logic, and user interfaces.

- Hardware Selection – Choosing the appropriate VFDs, PLCs, sensors, and panels.

- Programming & Configuration – Writing ladder logic, setting VFD parameters, and building HMI screens.

- Installation & Commissioning – On-site wiring, testing, and performance validation.

- Training & Support – Equipping your team to operate and troubleshoot the system effectively.

Xtreme Automation LLC ensures each step is handled professionally and efficiently to minimize disruptions and deliver long-term results.

Conclusion

Combining VFD and PLC systems creates a flexible, reliable, and intelligent solution for modern automation challenges. Whether you’re managing motors, improving process efficiency, or enhancing system control, this integration delivers measurable benefits in energy savings, equipment longevity, and operational visibility.

Partner with Xtreme Automation LLC to design and implement a VFD and PLC system customized to your facility’s specific needs. Their certified expertise and customer-focused approach ensure your automation project runs smoothly—today and well into the future.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments