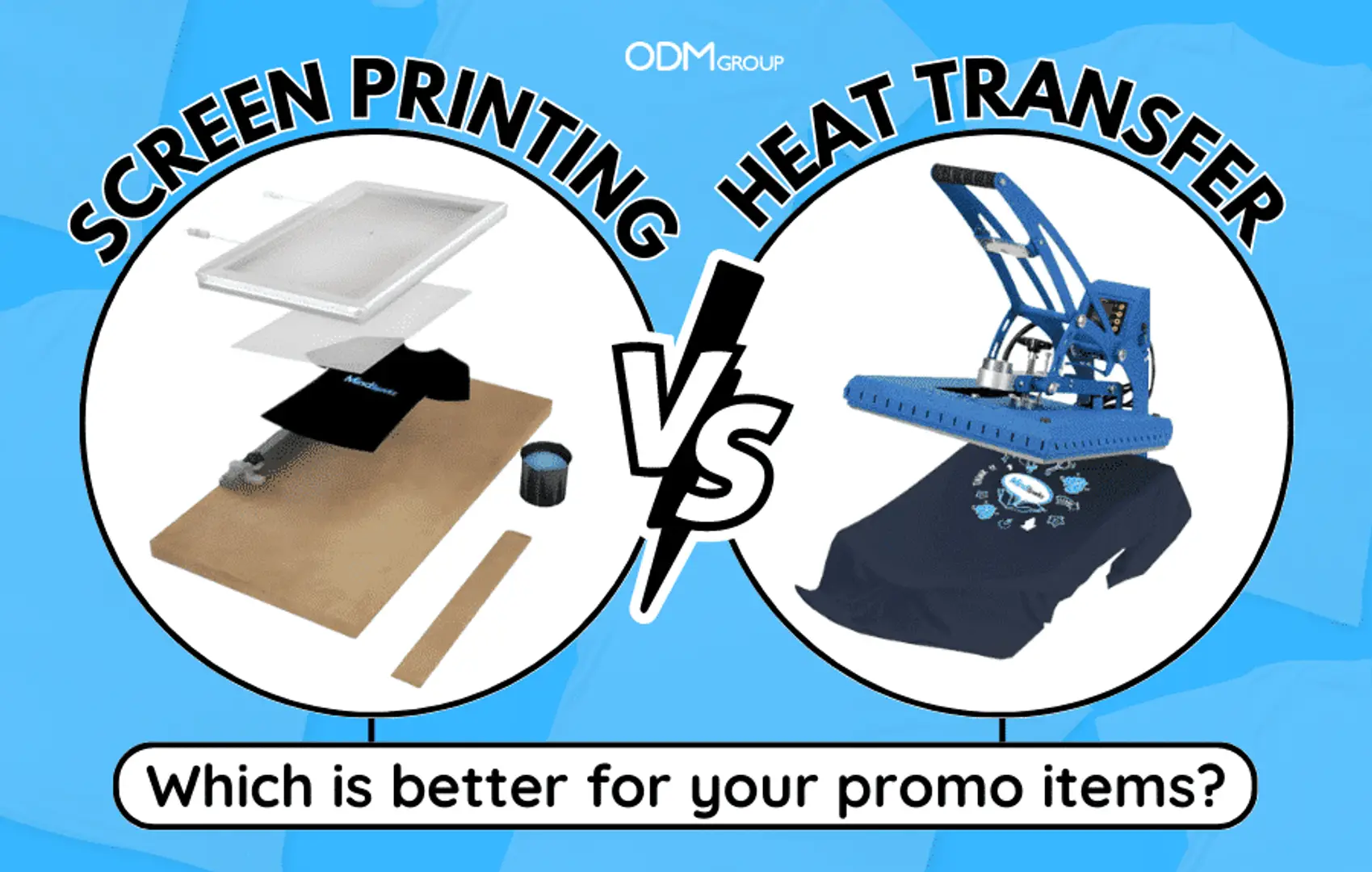

Which Printing Method Is Best: Heat Transfer or Screen Printing?

When you need to add personal touches to clothing, promotional products, or merchandise, choosing the best printing method is critical. Two of the most popular techniques—heat transfer and screen printing—both have pros and cons. Whether you’re a small business person, crafty do-it-yourselfer, or professional print shop, understanding heat transfer vs screen printing differences can help you make the ultimate decision for your needs.

What Is Heat Transfer?

Heat transfer printing is accomplished through heat and pressure used to print a design onto material or any surface. The design will typically be printed on transfer paper or vinyl and then heat pressed onto the material.

Advantages of Heat Transfer:

- Perfect for Small Orders: Ideal for small orders or specialty one-time runs.

- Detail & Color Variety: Can produce high-resolution prints with fine details and gradients.

- Low Setup Cost: Low setup time and equipment required.

Cons:

- Durability: May not be as durable as screen prints when washed many times.

- Slower for Bulk Orders: Each item must be pressed individually, which is a time-consuming process for bulk orders.

What Is Screen Printing?

Screen printing, or silkscreen printing, is a method of pushing temperature ink through a mesh screen stencil onto a surface. A separate screen is required for each color in the artwork, which makes it better suited to simple, bold graphics.

Advantages of Screen Printing:

- Very Durable: The temperature ink used in screen printing is well supported by fabric, producing prints that are very durable.

- Cost-Effective for Bulk Orders: After setup, it’s faster and cheaper for larger orders.

- Bold & Bright Prints: Ideal for solid colors and sharp images.

Drawbacks:

- Limited Color Palette: Poor choice for designs with many colors or gradient effects.

- Larger Initial Setup: More prep time and supplies are necessary, especially for multi-color designs.

Heat Transfer vs Screen Printing: Key Differences

Feature Heat Transfer Screen Printing

Best For Small runs, detailed designs Large orders, simple bold graphics

Durability Medium (wears off after a while) High (long-lasting impressions)

Setup Time Low High

Color Capabilities Full-color, photorealistic Limited, requires separate screen/color

Material Versatility Suitable for most surfaces Mainly fabrics and flat surfaces

Cost Efficiency Cheap for short runs Cheaper in volume

Which One Should You Use?

Selecting heat transfer vs screen printing is largely dictated by your project needs:

- If you’re printing a small number of products, need precise niceties, or want a full-color photo-quality image, heat transfer is the better option.

- If you’re printing large quantities, need long-lasting hardness, or want solid, bold graphics, screen printing is the better option.

The Role of Temperature Ink

In both methods, temperature ink plays a significant role. When using heat transfer, the ink must be capable of surviving high temperatures when being pressed without smudging or color change. When screen printing, temperature inks are fixed at high temperatures to provide durability, especially on clothes exposed to multiple washings.

Final Thoughts

There’s no one-size-fits-all answer in the heat transfer vs screen printing debate. It all comes down to your specific design, order size, budget, and desired durability. By understanding the strengths and limitations of each method, you’ll be better equipped to choose the perfect technique for your next printing project.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments