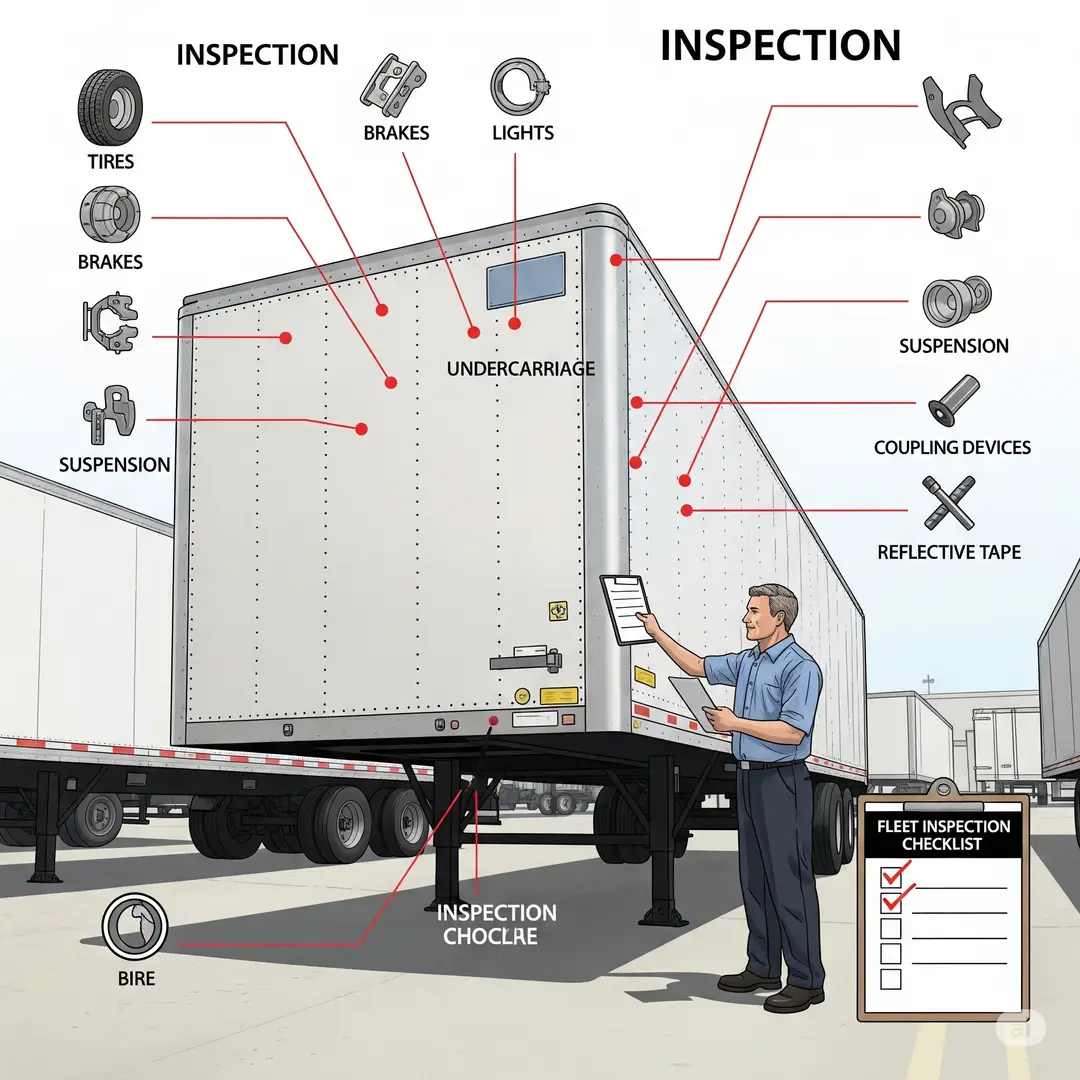

What to Look for During a Trailer Inspection: A Fleet Manager’s Checklist

Trailer repairs that come out of the blue have the power to unbalance your whole schedule. Whether it’s a small number of trucks or a large fleet, having trailers in good shape is absolutely necessary. A missed crack in the frame or a busted brake line can mean delays, fines, or worse, downtime that eats into your bottom line. That’s why having a solid trailer inspection checklist isn’t just smart, it’s survival.

This guide is built for the fleet manager, owner-operator, or ops guy who’s juggling dispatch calls, driver complaints, and broker emails all before lunch. Below, we break down what you really need to look for during a trailer inspection, so you can stay ahead of problems and keep those wheels turning. And when it’s time for trailer repairs, you’ll know exactly what to fix and why.

Start with the Basics: Exterior Walkaround

Before you pop open the toolbox, do a full walkaround. Look for anything that screams “problem” at a glance like dents, rust, cracks, or loose panels.

Key things to check:

- Landing gear: Make sure it raises and lowers smoothly. Bent legs or missing pins need attention.

- Frame and structure: Inspect for rust, corrosion, or cracks, mainly focused on the place where the parts come together.

- Lights and reflectors: All lights should be working, no flickers or busted bulbs. Reflectors should be clean and visible.

This step is quick, but it sets the tone. Spotting issues here often points to deeper trailer repairs that shouldn’t wait.

Tires and Wheels: Don’t Gamble on Rubber

Tires are easy to overlook until one blows out on I-40. Check pressure, tread depth, and signs of uneven wear. Uneven wear might mean alignment issues or a suspension problem brewing.

Quick tips:

- Minimum tread depth should be 4/32” on steer tires and 2/32” on others.

- Watch for sidewall bulges or embedded objects.

- Lug nuts should be tight and free of rust trails (a sign they’ve been loose).

- Check wheel seals any sign of grease on the hub or leaking oil needs a second look.

These issues can turn into costly trailer repairs if ignored.

Brakes: Your First Line of Defense

Brake issues are one of the top reasons for failed DOT inspections, and they’re no joke when it comes to safety.

Check the following:

- Brake pads or linings: Are they worn down?

- Air lines: Look for wear, chafing, or leaks.

- Slack adjusters: Are they adjusted properly?

You don’t need to be a brake expert, but you should know enough to call one when something’s off. Bad brakes will get your trailer parked roadside faster than a failed logbook.

Suspension: Smooth Ride = Less Wear

Suspension doesn’t just make for a better ride, it protects cargo, reduces driver fatigue, and helps prevent wear and tear on the trailer.

Inspect:

- Springs for cracks or missing leaves

- Airbags for dry rot, leaks, or misalignment

- Mounting hardware for looseness or rust

If your trailer is moving up and down more than it should or tilting to a single side, you should start talking to a mechanic.

Interior Condition: Floor, Walls, and Roof

Step inside. A lot of managers miss this part, especially if they’re busy moving trailers between loads, but it’s wrong to do so.

Here’s what to look for:

- Flooring: Check for rot, warping, or holes, especially on wood floors.

- Walls and roof: Look for water damage, punctures, or signs of previous patch jobs.

- Doors: Make sure they seal properly and lock securely.

Interior issues might not seem urgent until a customer rejects a load due to water damage or contamination. A quick inside check can save you thousands down the line.

Electrical & Air Systems

Pop the hood, or in this case, the connection points. Electrical and air systems are often out of sight, but they’re crucial for safe operation.

Checklist:

- Pigtail connectors: No frays or corrosion

- Glad hands: Gaskets in good condition, no leaks

- Wiring harnesses: No exposed wires or rubbing

Catch these early, and you can avoid bigger trailer repairs that take your equipment off the road longer than necessary.

Documentation & Compliance

Last but not least, make sure your paperwork is as tight as your hardware.

You’ll want:

- Current inspection stickers

- Updated maintenance logs

- Any repair history or warranties on file

This isn’t just about passing a DOT inspection, it’s about knowing your equipment inside and out. A fleet that runs on solid records runs smoother, period.

Final Thoughts: Inspections Save You More Than Money

Look, no one’s saying trailer inspections are fun. But they’re your first line of defense against downtime, customer complaints, and safety risks. Whether you’re turning wrenches yourself or managing a team, having a standard checklist ensures consistency, and consistency keeps rigs rolling.

When problems pop up (and they will), don’t put them off. Fast, professional trailer repairs are the difference between a small hiccup and a major financial hit. Get ahead of the problem, and your drivers, customers, and bottom line will thank you.

You built your business from the ground up. Don’t let avoidable breakdowns drag it down. Start with a solid inspection routine, and know when it’s time to call in the pros.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments