What are the key features of AVEVA MES that support real-time production monitoring?

A number of essential elements of the AVEVA Manufacturing Execution System (MES) enable real-time production monitoring, improving manufacturing operations’ visibility, effectiveness, and responsiveness.

A number of essential elements of the AVEVA Manufacturing Execution System (MES) enable real-time production monitoring, improving manufacturing operations’ visibility, effectiveness, and responsiveness.

Real-Time Data Collection:

Data may be gathered by AVEVA MES from a variety of sources, including as sensors, PLCs, SCADA systems, and human inputs. This makes it possible to track manufacturing processes, equipment status, and performance indicators in real time.

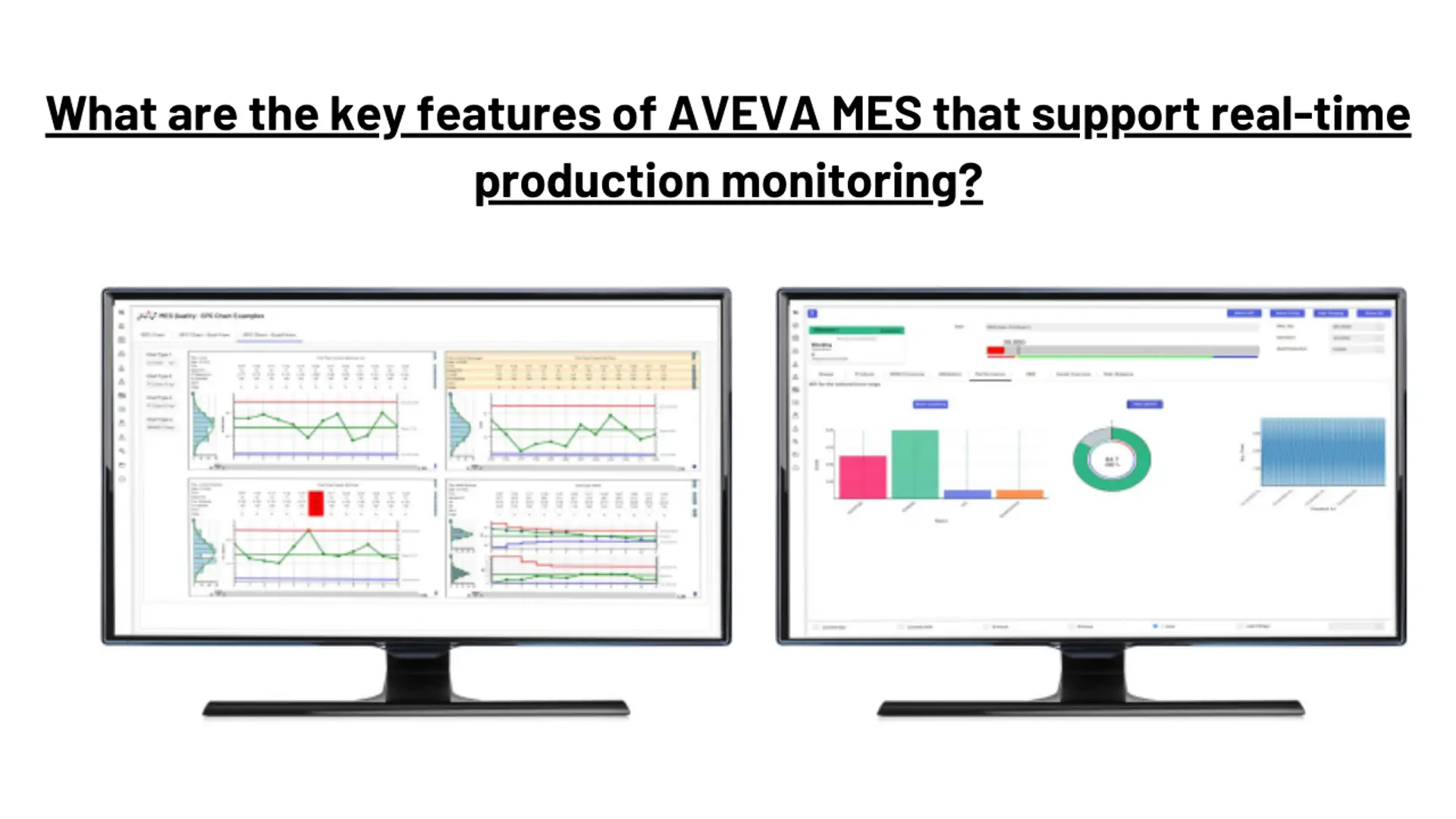

Dashboards and Reports:

The technology offers real-time insights into manufacturing processes through configurable dashboards and reports. Operators and managers may monitor key performance indicators (KPIs), detect problems fast, and make well-informed choices with the aid of these visual tools.

- Drill-Down Capabilities: Drilling down into certain data points allows users to look for problems or abnormalities. This capability makes it possible to analyse production events in depth and identify underlying causes quickly.

- Alerts and Notifications: Dashboards have the ability to show warnings and alerts for important events like equipment breakdowns, production halts, or quality problems. This guarantees that problems are dealt with quickly, reducing their influence on output.

- KPIs and Performance Metrics: Dashboards prominently include Key Performance Indicators (KPIs) and other performance indicators that give a clear picture of how effectively production is fulfilling objectives.

Event and Alarm Management:

Advanced event and alarm management features in AVEVA MES notify operators of any deviations from normal operating circumstances. This makes it possible to respond to problems quickly, reducing downtime and preserving product quality.

Maintaining compliance in sectors with strict regulatory standards necessitates efficient event and alarm management. AVEVA MES provides comprehensive records of all events and alerts, together with actions made in response, to assist manufacturers in complying with laws. The manufacturer’s strong methods for handling deviations and guaranteeing product quality are demonstrated by this paperwork, which is essential for audits and inspections.

Work Order Management:

Work order tracking in real-time guarantees adherence to production schedules and makes delays or deviations instantly apparent. This function aids in fulfilling delivery obligations and streamlining manufacturing.

Quality Management:

Real-time product quality monitoring is made possible by integrated quality management systems. This include monitoring quality metrics, handling non-conformances, and making sure industry standards are followed.

A vital part of AVEVA Manufacturing Execution System (MES) quality management skills is statistical process control, or SPC. Utilising statistical techniques, SPC monitors and regulates the manufacturing process to make sure it runs as efficiently as possible and yields goods that satisfy quality requirements.

Utilising SPC methodologies, AVEVA MES gathers data on a range of process parameters in order to spot trends and variances that may have an effect on the quality of the final product. The technology can identify when a process is spiralling out of control and notify operators to take remedial action by analysing this data. SPC contributes to process stability, variability reduction, and consistent product quality.

Performance Analytics:

With the ability to process data in real-time and deliver insights into production efficiency, equipment performance, and process bottlenecks, AVEVA MES is a strong analytics tool. This promotes operational excellence and aids in efforts towards continual improvement.

Traceability:

Throughout the whole production process, the system guarantees complete traceability of the goods and supplies. Batch, lot, and serial number tracking in real time improves regulatory compliance and quality control.

Resource Management: AVEVA MES monitors the availability and use of resources, such as labour, equipment, and raw materials. In addition to ensuring optimal use, this helps prevent production delays caused by resource constraints.

Mobility and Remote Access: By enabling operators and managers to monitor production processes and make choices from any location, AVEVA MES enhances responsiveness and flexibility. It also enables mobile devices and remote access.

Teams may collaborate more effectively regardless of where they are physically located thanks to mobility and remote access. Multiple people may examine the same real-time data and work together to solve problems and make decisions using AVEVA MES. This cooperative method is critical in complicated production settings where prompt and well-coordinated response is required.

The capability of AVEVA MES’s remote access to do remote maintenance and troubleshooting is one of its primary features. Without having to visit the location, engineers and technicians may obtain equipment data, identify problems, and put fixes in place. For international operations or sites situated in remote areas where it is not always possible to be physically present immediately, this feature is very important.

By providing real-time production monitoring capabilities, AVEVA MES gives firms more visibility, efficiency, and control over their production processes. Manufacturers may get increased production, superior quality goods, and more effective operations by using these essential qualities.

Related Posts

© 2025 Invastor. All Rights Reserved

User Comments